The higher the receiver temperature, the more efficiently a solar thermal power plant will operate. Convective thermal losses also have an important effect on yield. The HelioGLOW collaborative project by Fraunhofer Institute for Solar Energy Systems ISE and industrial partners is working to address these challenges: The project team investigated a novel ceramic heat-transfer medium including power plant design and air wall for the thermal insulation of the receiver. The trend toward continuously improving production processes is reflected in the development of the Stellio heliostat.

The results of the project are presented in the recently published final report (in German).

Conventional solar tower power plants work with molten salt as a heat-transfer medium, which imposes a temperature limit: Above 600°C, the corrosiveness of the salt will cause damage. The HelioGLOW project works with a solid-state heat-transfer medium, which allows for an operating temperature of more than 1,000°C, considerably boosting efficiency.

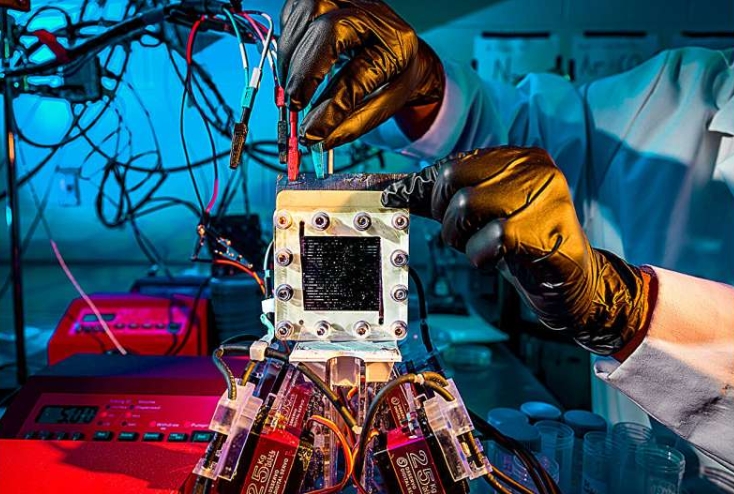

The heat-transfer medium is driven though the receiver through a bespoke process reminiscent of a carousel, and heated up immediately. To this end, Kraftblock GmbH developed novel ceramic receiver elements made of non-corrosive, environmentally friendly material with a high heat storage capacity. The ceramic material is produced in a recycling process, which makes it cost-efficient.

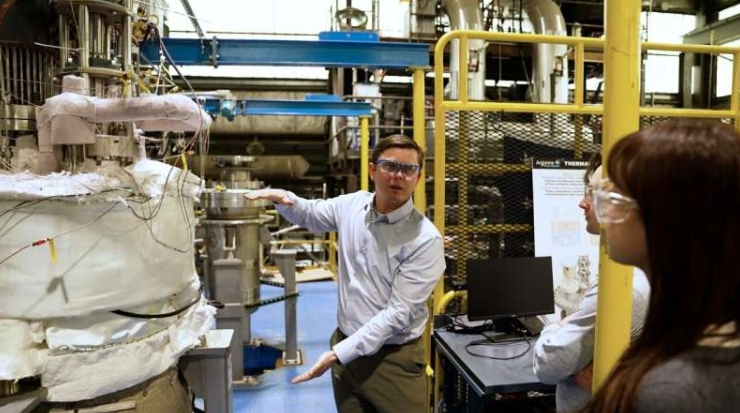

The material's temperature development and stability were characterized at a Fraunhofer ISE test stand, followed by tests in the solar simulator at the IMDEA Energy Institute in Madrid. The project team was able to use the measuring results as a basis for analyzing the material's behavior under extreme solar radiation. "The next goal will be to further develop the receiver's material to enable the energy to be transmitted deeper into the body," explains Dr.-Ing. Gregor Bern, Group Manager Concentrating systems and technologies at Fraunhofer ISE.

The novel solid-state receiver combines radiation receiver, heat-transfer medium and storage material, reducing the costs for power plant construction. Heat transfer resistance and limitations of flux density like in conventional tube receivers are eliminated. The resulting higher temperature, which can be maintained better even when solar radiation is fluctuating, also contribute to reducing the costs of solar thermal electricity generation.

Air wall reduces thermal loss by 30%

Solar power towers typically face convective thermal losses, which reduce the efficiency when the temperature is high and solar irradiation has a high concentration. While the air temperature on the receiver can go up to 600°C, the temperature of the ambient air is normally around 30°C to 40°C. Heat from the receiver is transferred to the cooler air as it flows past it. A separation of different air volumes can be achieved by quartz glass panes, which are not available in the required size, however.

To overcome this problem, Fraunhofer ISE tested the idea of an "air wall" generated by powerful nozzles on the receiver's opening to separate the air volumes.

"Until recently, there had only been simulations for this solution, but the technology had never been demonstrated in an actual power plant," explains Moritz Bitterling, research associate in the Fraunhofer ISE project team.

A regular size test setup equipped with ca. 50 temperature sensors was used to simulate a receiver at 600°C using heating elements. Our industrial partner, Luftwandtechnik GmbH, designed an air wall system specifically for high-temperature applications and installed it at the receiver test stand at Fraunhofer ISE in Freiburg. Using this setup, convective thermal losses with an air wall were compared with those without an air wall, measuring the heating power necessary to achieve 600°C. The suitable operating parameters, such as the angle of the air wall nozzles and the air outflow speed were agreed with Luftwandtechnik GmbH. The receiver's convective thermal losses could be reduced by 30%. This technology is also suitable for other industries working with high-temperature processes, where the separation of major temperature differences on furnaces etc. can reduce losses. The project partners are planning to test this in follow-up projects.

Where solar thermal electricity generation is concerned, there is a trend towards smaller solar power towers. This is why, in the HelioGLOW project, Fraunhofer ISE and sbp sonne GmbH are working on further developing their Stellio heliostat. The goal was an optimized pylon design and the adaptation of the design to the requirements of smaller solar power towers in order to further reduce costs. Fraunhofer ISE used 3D laser scanning to measure the heliostat's parameters and tested processes for quick heliostat measurements in the field. Deflectometric measurements of the reflector surfaces in the laboratory was used to analyze the deformation effects under specific load scenarios.

The team at Fraunhofer ISE then developed an overall concept based on all of the components mentioned above, integrating the solid-state heat-transfer medium receiver, the air wall and the optimized Stellio heliostat into a solar thermal power plant. The researchers evaluated which power plant process is best suited for coupling and how the heat can be transferred from the solid-state material to the power plant process. The overall system was modeled, examined and its technical and economic performance was evaluated using the thermo-hydraulic simulation tool ColSim CSP. This was able to expand on the existing technical-economic models and identify the ideal layout and operation for a power plant with the new components.