To meet the new emissions standard, it was clear the turbine required a retrofit solution.

To meet the new emissions standard, it was clear the turbine required a retrofit solution.Governments around the world are cracking down on nitrogen oxide (NOx) emissions, not only for transport, but gas turbines as well, with operators having to invest in equipment to meet ever stricter standards. To ensure a 500 MW combined cycle powerplant at Tongzhou in China could meet new legislation, Sulzer engineered a customized combustion automatic tuning adjustment system (CATS). The advanced, closed loop solution has avoided the large capital expenditure (CAPEX) and long lead times of flue gas denitration and burner upgrades - all while securing gas turbine efficiency through balancing key parameters in operation.

Meeting a new emissions standard

In 2021, Jiangsu Province in China announced its “Stationary Gas Turbine Air Pollutant Emission Standard”, which stipulated that by March 2023, all gas turbines in the area will have to attain a NOx emission limit 30 mg/m3 (standard state, dry basis, 15% O2). This presented a powerplant in Tongzhou with a challenge. The plant’s Siemens V94.2 gas turbine was found to be emitting between 35 to 45 mg/m3 of NOx during normal running. To meet the new emissions standard, it was clear the turbine required a retrofit solution.

Operators at the powerplant approached Sulzer, a global independent service provider (ISP) for rotating equipment with unmatched heritage. From a worldwide network of specialist service centers, Sulzer provides world-class repairs and upgrades for all types of turbomachinery. With its relentless approach to innovation, Sulzer offers market-leading solutions to meet the modern operating demands of gas turbines. Consequently, the company was a natural choice to partner with in identifying the best approach to reduce emissions.

Choosing an optimal solution

The first option explored by Sulzer was flue gas denitration. Similar to diesel vehicles using AdBlue, a urea solution would be introduced into the gas stream to carry out selective catalytic reduction (SCR) - a well-established method for reducing NOx emissions. However, as the turbine did not have this system fitted, it would require a CAPEX of around USD 2 million and an annual operating expenditure (OPEX) of USD 685’000.

A more cost-effective option was a burner upgrade. However, a low NOx burner cartridge replacement would still equate to a USD 342’000 CAPEX and an annual USD 137’000 OPEX. As well as being high-cost solutions, both options would have long lead times and associated downtime, not ideal for a power generation application.

Sulzer instead proposed a more advanced solution. By balancing the parameters of combustion within the gas turbine, it was possible that the emissions standard could be met. This would require a CATS, which could provide real-time, dynamic control of the process. Its key function would be to optimize combustion stability by identifying and reacting to operational thresholds, keeping NOx emissions under the legislative limit. Sulzer estimated that such a system could be developed, tested and implemented for around USD 685’000. Key advantages included a relatively short turnaround time and minimized OPEX once the system was up and running.

Defining key combustion characteristics

Before the CATS could be designed, it was important to identify the key combustion characteristics. This would involve gathering large quantities of data regarding turbine combustion, NOx generation and existing controls. For over six months, Sulzer collected and analyzed tens of thousands of sets of unit operating data, discerning the characteristic values for thresholds that, if exceeded, would affect burn stability and NOx emissions. This would help create the control model that the CATS would adhere to.

Extensive research was conducted on the turbine itself. As part of this, combustion tuning testing was carried out in varying operational conditions, allowing for parameters to be assessed. Throughout all testing, continuous NOx emissions monitoring was conducted to show how certain parameters affected emissions. The key was to achieve the emissions standard without reducing the efficiency of the gas turbine.

The results showed that NOx emissions were being affected by combustion temperature, fuel variability, humidity, ambient temperature and a phenomenon known as humming. Humming refers to pressure oscillations caused by combustion instabilities. To create an automatic control system, all of these factors would need to be measured using sensors. This signal data would then require processing and applying to the operational threshold values discovered during research. Then a control model could be realized for stable combustion, allowing the new emissions standard to be achieved.

Turning data into action

Based on the findings and analysis, Sulzer developed the modular control system in-house, carrying out control strategy design, control logic configuration and simulation verification. The system is designed to seamlessly integrate with the control system currently installed on the gas turbine. A custom key data display was also implemented, showing signal data from different parameters including NOx, humming, natural gas heat, humidity and temperature.

Functionality available from the bespoke control interface includes dedicated modules for auto-fuel adjustment, a combustion stability control, NOx emissions reduction, performance optimization control, fuel calorific value manual input function, function status display, alert alarm and a historical graph.

A controlled burn

In operation, the CATS provides closed loop control, using feedback from sensor signal data to keep operational parameters within the desired thresholds. If any signal value exceeds the desired range, automatic dynamic adjustments are made to ensure that key parameters such as emissions, combustion dynamics, power output and efficiency are maintained. Furthermore, using historical data gathered during research and operation, feed forward control is also possible. Using models to make predictions on burn stability in different conditions, the system can also take proactive actions to control the burn. This aspect of the system becomes more proficient as data is collected, recalibrating the characteristics of the individual turbine accordingly. All this ensures that NOx emissions are reduced during running, as the gas turbine is prevented from straying into unfavourable operating conditions.

Across a range of loads, gas calorific values, humidity and ambient temperatures, the CATS was able to deliver average emissions below the 30 mg/m3 standard. In fact, since its installation, the highest instantaneous value of NOx emissions from the turbine is lower than 28.5 mg/m3, with an hourly average of just 27 mg/m3 – 25% to 30% lower than the average NOx emission value in 2020.This ensures that the turbine now meets the “Stationary Gas Turbine Air Pollutant Emission Standard” coming into effect in Jiangsu Province.

Innovating for legacy gas turbines

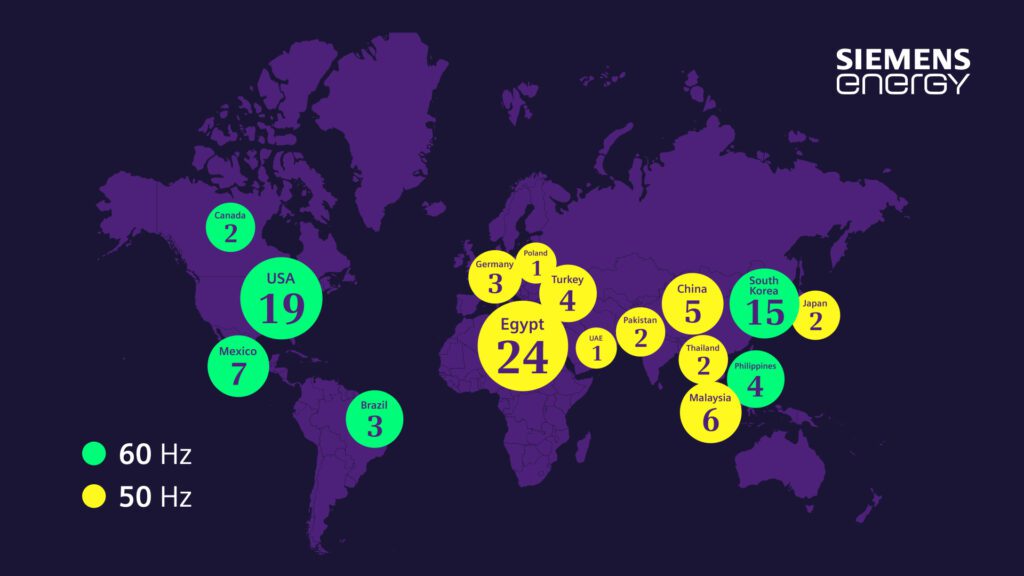

This breakthrough CATS solution has provided the power plant with a one-off CAPEX saving of USD 1.4 million, while delivering OPEX savings of over USD 41’000 per turbine annually. The system has reduced emissions by 120 tonnes in its first year of operations, unlocking annual carbon tax savings of nearly USD 44’000. Furthermore, the CATS is fully applicable to other selective Siemens, General Electric and Mitsubishi heavy duty GT models, ensuring these multiple advantages can be attained by other combined cycle and gas power plants.

Sulzer’s in-depth industry and solution engineering expertise, offer power plants the gas turbine expertise required to achieve stable combustion performance and reduced emissions reliably and cost-effectively. With a proven, bespoke control solution, legacy turbines can be modernized to attain new efficiency standards, while avoiding the long lead times and investment required for replacement equipment. With emissions standards around the world becoming more prescriptive – a trend that is set to continue – operators now have access to a new technical innovation that can breathe new fire into their efforts to reduce emissions and improve efficiency.

Sulzer’s in-depth industry and solution engineering expertise, offer power plants the gas turbine expertise required to achieve stable combustion performance and reduced emissions reliably and cost-effectively.