New research from the University of New South Wales (UNSW), published in July 2024, has proposed an established process to help further scale tunnel oxide passivated contact (TOPCon) solar.

The researchers say their approach to solar cell construction – outlined in Ultra-Lean Silver Screen-Printing for Sustainable Terawatt-Scale Photovoltaic, published in RRL Solar – could reduce TOPCon silver content from between 12 mg/W and 15 mg/W down to 2 mg/W. That would keep the solar industry’s silver consumption below 20% of global supply as PV expands.

The paper’s authors have claimed 24.04% cell efficiency using their approach, and said that cells manufactured in Chinese partner facilities have been measured at 26.7% efficiency.

The study included partners from metal paste production and PV manufacturing. It was led by Brett Hallam, associate professor at the UNSW School of Photovoltaic and Renewable Energy Engineering.

“The industry, generally, has not been thinking ahead,” said Hallam. In 2021, he conducted research on the technology PV manufacturers should adopt beyond passivated emitter rear contact (PERC) solar. The study, “Design Considerations for Multi-terawatt Scale Manufacturing of Existing and Future Photovoltaic Technologies: Challenges and Opportunities Related to Silver, Indium and Bismuth Consumption,” was published in Energy and Environmental Science.

In this paper, Hallam dismissed expectations that more efficient heterojunction (HJT) solar would replace PERC, arguing that the indium required in the indium tin oxide layer – a transparent, conductive oxide – would only allow for 200 GW of production before depleting the world’s indium reserves.

“There’s always a big push for efficiency of solar cells,” said Hallam, when people see “the cliff that’s coming with the exponential growth in installations needed to mitigate climate change.”

Magic pastes

The team’s eureka moment came in 2020, thanks to the PhD research of Yuchao Zhang, a co-author of both aforementioned papers.

“Initially, my work was focused on improving cell efficiency, and then we identified silver consumption might be an issue,” said Zhang. “Based on this particular design I was working on, we thought there was potential to cut the silver consumption by up to 90%.”

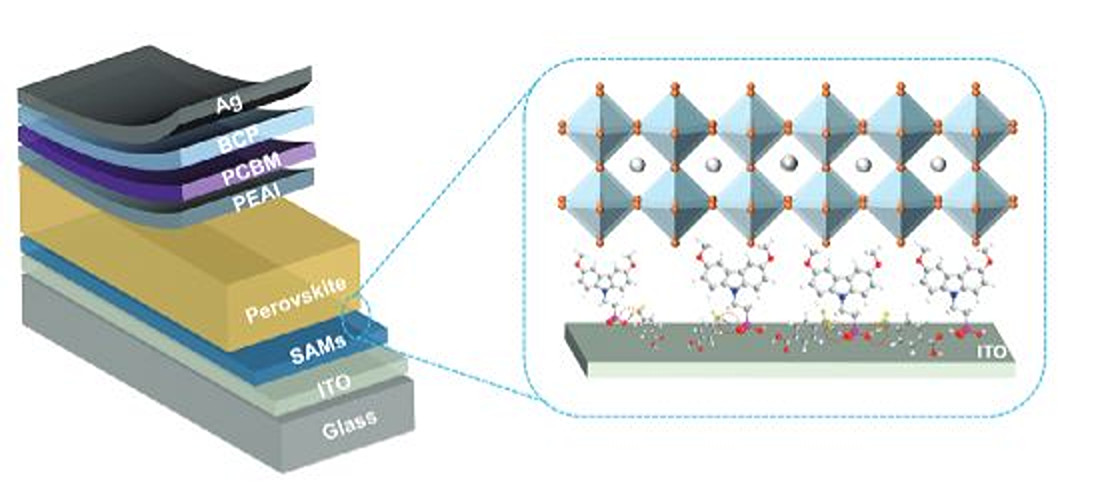

Their latest approach, recently published in RRL Solar, “uses screen-printed dots and dashes of silver paste for critical functions” such as conducting energy from the silicon, and for a second screen-printed layer of “cheaper, abundant [but less conductive] materials for flowing that electricity,” explained Hallam.

Where typical silver-content-reduction approaches can encounter finger breakages, resistive losses and reliability issues, the less-restricted fingers of UNSW’s non-silver top layers offer additional conductivity, maintaining or surpassing the efficiency of conventional silver finger designs.

“The initial problem was that we had the design but we didn’t have a suitable non-silver paste to test with,” said Zhang, explaining that collaborators such as Japan’s Toyo Aluminium started developing “some amazing new pastes” that tested well and brought this design to a new level that could be used in mass production.

Hallam said copper and aluminum “are two obvious candidates for the finger layers; each comes with potential challenges, but we believe they are all solvable.”

The UNSW design uses silver paste from Shanghai-based project partner Changzhou Fusion New Material Co. The paper states that the use of conventional silver pastes for the critical function of metal/Si interface formation delivers benefits from decades of improvements from silver paste developments and optimizations.

“We’re hoping Toyo and Fusion, and others, will look at developing next generation pastes that are tailored to our technology and will further enable this metallization approach,” said Hallam.

Partner perks

The screen-printing approach, in common with previous UNSW research, is compatible with current production processes. It can function with PERC and TOPCon lines without new tooling.

“We designed this approach with existing printing capabilities – alignment, tolerance, printing widths – in mind,” said Hallam.

Test runs have been carried out by manufacturers. “The pastes are designed for mass production so you need to be continuously printing,” said Hallam. “Their viscosity changes if you’re only doing small test runs. Results in our industrial partner facilities are much better than we could achieve in the lab at UNSW.”

Cost implications

Zhang and Hallam conceded that copper plating technology may ultimately win out in terms of sustainability, so they have also been investigating hybrid approaches combining the strengths of screen printing with those of the plating processes used in copper metallisation. That adds a layer of complexity, however, and will initially negate the cost advantages of silver reduction.

“There are not many equipment manufacturers currently producing the plating tool,” said Zhang. “Material-wise, you can definitely save some money on the silver paste by moving to plating. But the plating tool is much more expensive and your yield in the mass production process is not as high as with screen printing.”

New pastes may not at first reflect the far lower costs of using copper or aluminum instead of silver. Hallam said paste makers could initially charge a premium for their new formulas, knowing the alternative is high-priced silver.

“Over time, we think these copper or aluminum pastes, or whatever we use, can be produced way, way cheaper than the silver pastes,” he said. “Inherently, changing to non-silver pastes will save money, potentially up to $0.01 or $0.02/W.”

He calculated that a big company producing 10 GW to 20 GW annually could save around $50 million per year.

Hallam said the technology can be introduced in stages, cutting costs almost immediately. “We can already do everything on the rear surface, where we’re less restricted on shading,” he said, adding that, on the front surface, “we’re working on maintaining narrow fingers of the non-silver pastes.” This type of challenge is best solved by the industry, he explained, noting that “our existing partners have a head start on the rest of the industry.”

The associate professor said the time has come to invite new partners to participate in progressing the designs and reap the rewards of both cost reduction and sustainability.

“With what we’ve achieved already, we believe it’s absolutely feasible that, at 2 mg of silver per watt, the world can produce 3 TW of solar cells a year using 20% of the global silver supply. That’s a manageable level for the foreseeable future.”

Some of the outcomes in the RRL Solar paper have already been superseded by subsequent improvements – such as increased conversion efficiency in newer designs. Hallam noted that some of the numbers are relatively conservative, adding, “I think we’ll probably drive the silver content even lower.”

Unscrapping silver

The International Renewable Energy Agency estimates up to 8 million tons of spent PV materials will need to be processed by 2030, and 78 million tons by 2050. A study released in March 2024 by the Australian Centre for Advanced Photovoltaics recommended the establishment of large waste facilities in five big Australian cities by 2027.

Although it may be a long time before recovered materials such as high-value silver can achieve meaningful circularity in terawatt-scale solar production, PV manufacturing is just one major user in a world of limited silver resources. The value of silver is one reason why global researchers are still working on finding sustainable means of extracting it from PV waste.

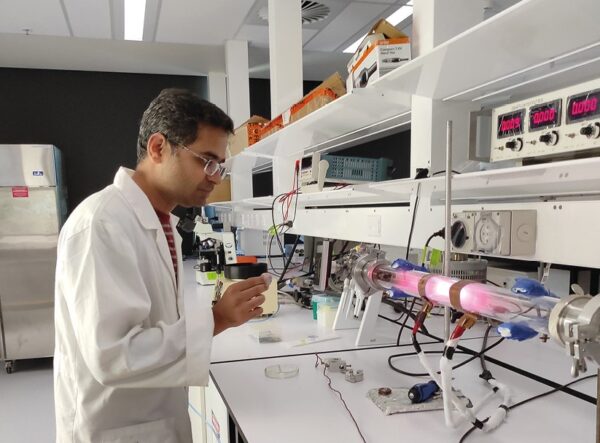

Materials engineer Muhammad Adeel Zafar is passionate about bringing more sustainable practices to solar production and the recycling of solar waste.

In Zafar’s PhD research, completed in 2023 at James Cook University (JCU) in Queensland, he synthesised graphene from plant extracts – notably tangerine peel oil. He won the Dean’s Award for his first-time fabrication of nitrogen-doped graphene oxide in a single step at ambient conditions.

“Tangerine peel has the one essential element, carbon, that we need for graphene, which is basically carbon arranged in a hexagonal structure,” said Zafar. “On top of that, tangerine peel is a waste product. So I thought, ‘why not’.”

“Graphene is a future material with very wide application for its electrical, mechanical, lightweight, and transparent properties,” added Zafar.

In subsequent tests conducted by his research group, graphene-coated electrodes showed an efficient capacity in a process for extracting silver from mixed PV waste materials, including indium tin oxide, zinc oxide, molybdenum oxide and silver, suspended in a nitric acid solution.

Zafar’s team – led by Prof. Mohan Jacob, head of electrical and electronics engineering at JCU – presented their novel work in “Green synthesis of graphene for targeted recovery of silver from photovoltaic waste,” published in Chemosphere.

“Our approach of creating a graphene-silver composite directly from waste material offers environmental benefits, resource utilisation, waste reduction, and versatile applications in electrochemistry,” they said in the abstract.

The group is now seeking partners and investors to scale up its method of silver recovery from PV material and to build out from that first natural tangerine peel resource to “a completely green, sustainable, and chemical-free process,” said Zafar.