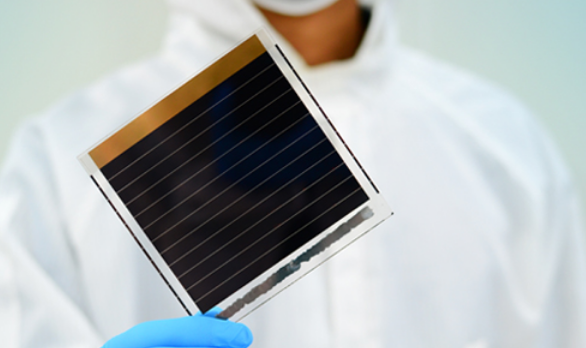

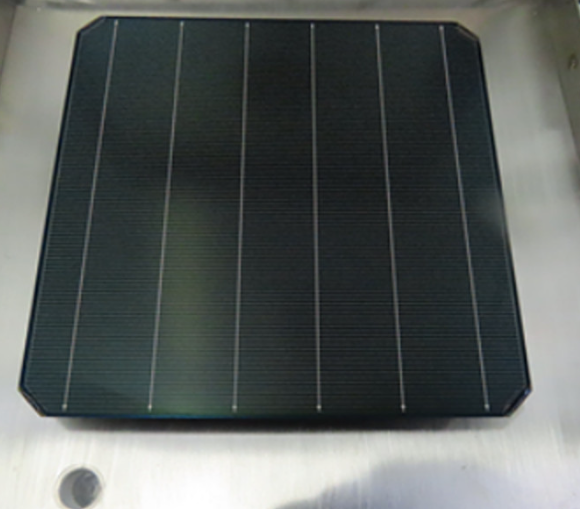

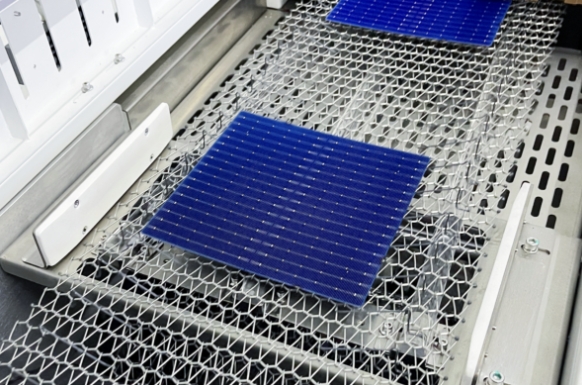

The plant has completed construction, production line setup, and initial manufacturing of high-efficiency n-type solar cells, which boast an average conversion efficiency of 26.4% and reliable output power. SEG Solar stated: “The commissioning of the plant’s first production line signals the full-scale operational launch of the project’s first phase which is to include four production lines with a total capacity of 2 GW.” The facility employs advanced double-sided alternating screen-printing equipment, achieving a cycle time of 0.75 seconds per cell, 20% faster than industry norms.

The factory is designed to expand to a 5 GW annual capacity, with plans to establish a fully integrated supply chain in Indonesia, encompassing silicon rods, wafers, cells, and modules. This development positions the Batang plant as a key hub for solar manufacturing, enhancing Indonesia’s role in the global renewable energy supply chain. SEG Solar noted: “Its successful commissioning offers a replicable model for attracting more PV manufacturers and enhances the park’s industrial cluster effect.”

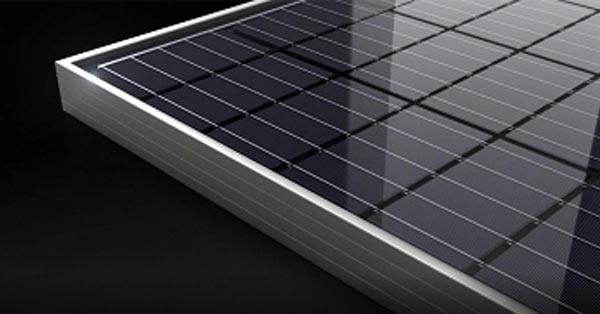

As one of the first solar projects completed in the Batang industrial estate, the facility is expected to draw additional renewable energy businesses to the region. The plant’s output, including solar cells and panels, will supply SEG Solar’s module factory in the United States and serve markets in the U.S., Europe, and Indonesia, delivering sustainable, traceable energy products.

The Indonesia facility represents a strategic shift for SEG Solar, moving from module production to upstream solar cell manufacturing. This expansion strengthens the company’s ability to meet growing global demand for clean energy solutions while fostering economic growth in Indonesia through job creation and industrial development. The rapid completion of the plant underscores SEG Solar’s commitment to advancing renewable energy infrastructure worldwide.