The collaboration has developed a pioneering process to extract and purify lithium from black mass—the shredded electrodes of batteries with chemistries like nickel-manganese-cobalt (NMC) and lithium-iron-phosphate (LFP)—using a single operating line. This streamlined approach enhances versatility, simplifies recycling, and may reduce capital costs, supporting efficient material recovery for domestic and regional use.

Laurent Cohen, Strategic Development and Alliances for Mining Solutions at Syensqo, stated: “Syensqo’s technology perfectly complements cylib’s hydrometallurgical process, enhancing both the yield and purity of recovered lithium. By combining our expertise in solvent extraction with cylib’s process, we’re establishing a scalable, high-purity lithium recovery route aligned with Europe’s circular economy and battery regulation goals.” The process utilized hundreds of liters of cylib’s lithium-rich effluent, processed with Syensqo’s innovative extraction technology, co-developed with Tenova Advanced Technologies. The technology employs CYANEX® 936P, a proprietary solvent extractant known for its high lithium selectivity.

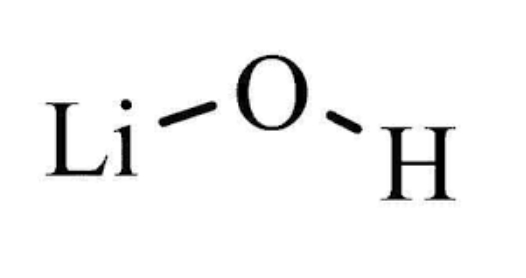

After extraction, purification, conversion, and crystallization, the resulting lithium hydroxide meets or exceeds the stringent purity standards required by leading cathode active material manufacturers. This ensures the recycled material is suitable for high-performance EV battery production.

Matthias Breidenbach, Vice President Commercial at cylib, highlighted the partnership’s impact, saying: “This collaboration with Syensqo demonstrates our commitment to working continuously with partners to develop new processes and expand our technological leadership in battery recycling. By combining our innovative hydrometallurgical expertise with Syensqo’s advanced solvent extraction technology, we are setting new standards for lithium recovery efficiency and purity.”

This milestone supports the European Union’s Battery Regulation (EU) 2023/1542, adopted in 2023, which mandates that recyclers recover at least 50% of lithium from battery waste by the end of 2027 and 80% by 2031. The Syensqo-cylib collaboration advances these goals, contributing to a sustainable circular economy by enabling the reuse of critical materials in battery production.