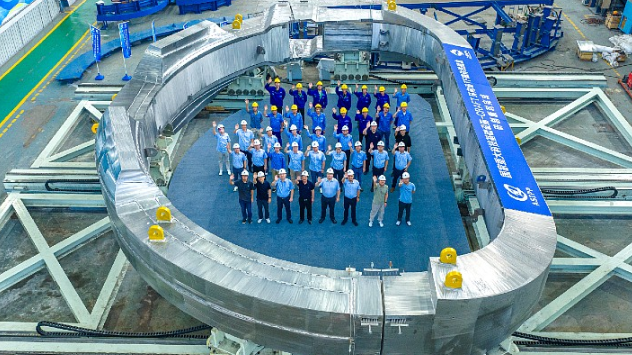

The project team spent five years addressing technical challenges. The Chinese Academy of Sciences’ Institutes of Physical Science highlighted innovations including high-thickness laser welding, ultra-deep narrow-gap tungsten inert gas welding, phased array non-destructive testing, and precision forming for 30-meter-long space bends. Techniques were also developed for cooling tube fixation using low-temperature resin and brazing, enabling high-precision installation.

The facility noted: “The successful delivery of the coil box not only accumulates relevant technical experience for the manufacturing of high-end equipment for China’s fusion devices, but also fosters a comprehensive, end-to-end industrial supply chain system, marking a significant step towards the commercialisation of fusion energy. The related technologies can also be applied in aerospace, energy equipment, shipbuilding, and offshore engineering.”

Shanghai Electric emphasized that the project demonstrates its innovation and high-end manufacturing capabilities. Earlier, in July 2025, the company collaborated with the Institute of Plasma Physics to complete the design and delivery of the magnet cold test cryostat for ITER in France. The cryostat, measuring 22 meters by nearly 11 meters and weighing 330 tonnes, was transported 104 kilometers from the port of Berre-l’Étang to the construction site in Cadarache. It will house D-shaped toroidal field coils and the PF1 poloidal field coil.

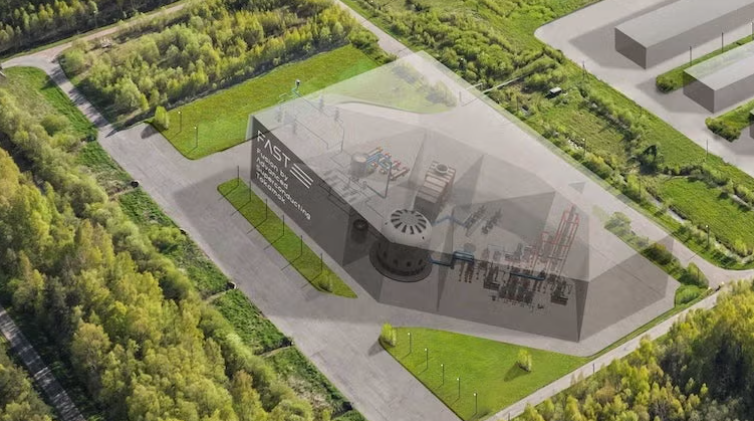

With over two decades of experience in fusion technology, Shanghai Electric noted that industrialisation is key to technological breakthroughs and commercial applications. The CRAFT facility in Hefei, now in its final construction phase, integrates around 20 specialized test stands, covering superconducting magnets, heating and current-drive systems, blankets, and tritium technologies. Its goal is to address engineering integration challenges as China advances magnetic fusion energy toward functional power plants.

The BEST tokamak, being built adjacent to CRAFT, will focus on steady-state control of deuterium-tritium plasmas and tritium production, extraction, and recycling. Civil works began in 2023, targeting first deuterium plasma by 2027, with deuterium-tritium operation plans under review.

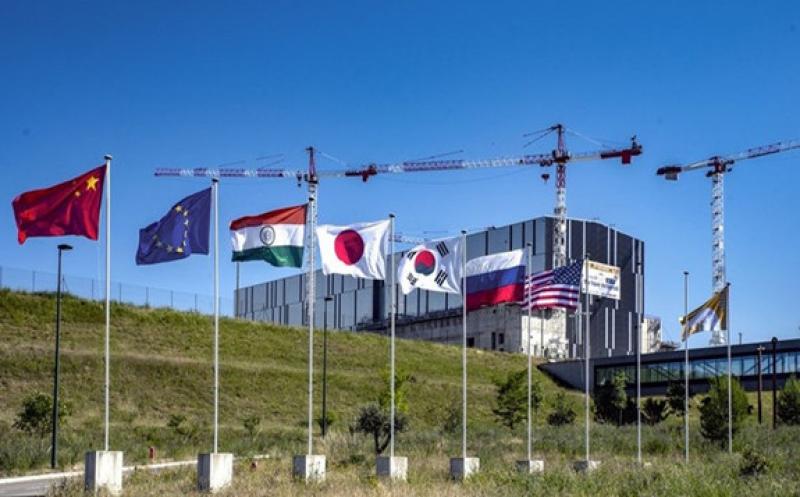

By comparison, ITER is an international tokamak project involving 35 nations to demonstrate fusion feasibility as a large-scale, carbon-free energy source. ITER aims for 500 MW output with 50 MW plasma heating input. Construction started in 2010, with first plasma initially targeted for 2018 and now revised, including deuterium-deuterium fusion by 2035 and full magnetic energy and plasma current operation thereafter.

This delivery of the toroidal field magnet coil box represents a major milestone for China’s fusion energy development, advancing both technical expertise and industrial capability in high-end energy technologies.