The O Mon 1 plant comprises two units, each with a capacity of 330MW.

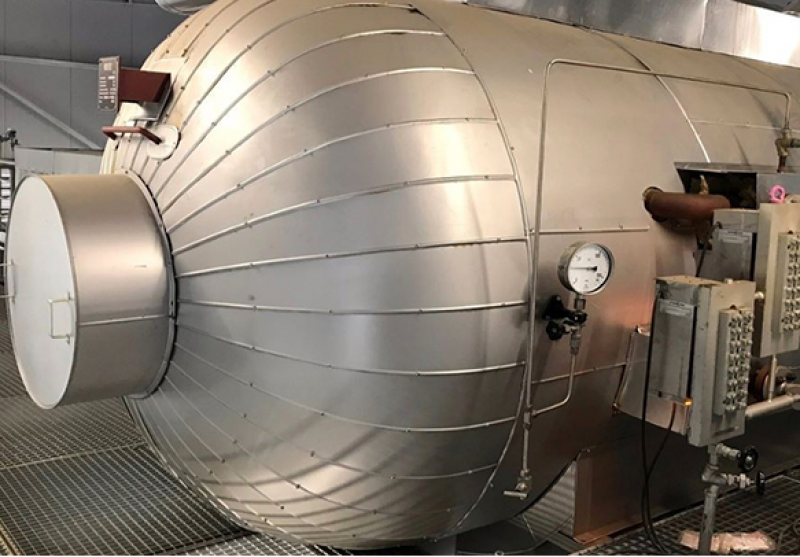

As a power solutions unit of Mitsubishi Heavy Industries (MHI), the company will supply gas burners for the plant's boiler. Drawing on its role as the original equipment manufacturer, Mitsubishi Power will manage the conversion process to lower carbon dioxide emissions.

Additionally, it will install a selective catalytic reduction system to neutralize nitrogen oxides in exhaust gases, aligning the facility with upcoming environmental standards.

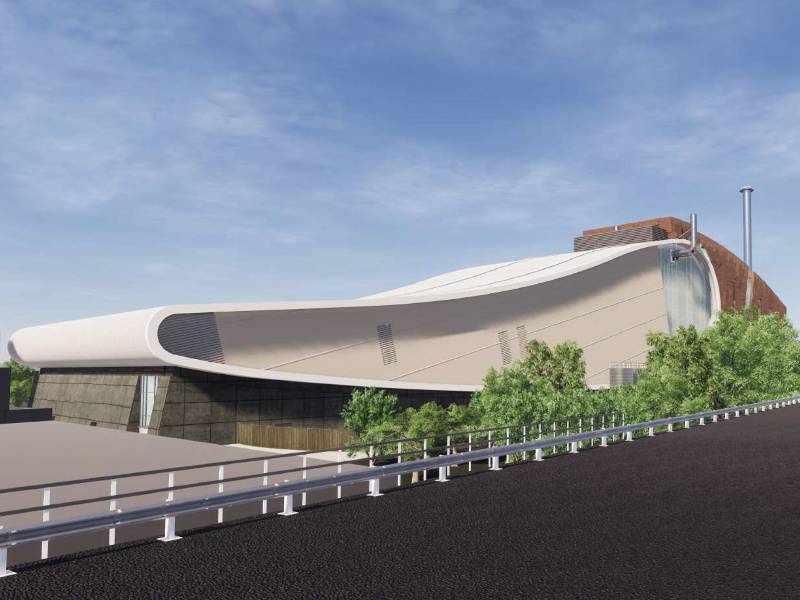

The O Mon 1 plant features two units of 330MW each, operational since 2009 and 2015.

Power Generation Corporation 2 (EVNGENCO2), under Vietnam Electricity Corporation (EVN), oversees the conversion initiative.

A consortium of LILAMA Corporation—affiliated with Vietnam’s Ministry of Construction—and EVNGENCO3, another EVN entity, handles engineering, procurement, and construction. This group awarded the primary equipment contract to Mitsubishi Power.

Mitsubishi Power Asia Pacific, within MHI Group, will execute EPC services and station technical experts for ongoing support.

Makoto Fujita, senior general manager of MHI’s steam power business division energy systems, stated: “Since the start of operations for Unit 1 in 2009, the O Mon 1 Thermal Power Plant has played an important role in the development of the Mekong Delta region. As the OEM of the existing power plant, we are extremely proud to be able to contribute to the stable supply of energy and decarbonisation in Vietnam through our participation in this fuel conversion project. We will devote our full effort to completing this project, and provide support for the long-term, stable operation of the plant.”

In August 2025, Mitsubishi Power secured another order to furnish two J-series air-cooled gas turbines for the adjacent O Mon 4 combined-cycle plant, planned at 1,155MW capacity and targeted for completion in 2028.

This dual involvement highlights Mitsubishi Power’s expanding footprint in Vietnam’s energy infrastructure. The O Mon complex serves as a cornerstone for regional electricity supply, supporting industrial and residential needs in the Mekong Delta.

Natural gas adoption offers a practical pathway to reduced emissions compared to oil, with the conversion preserving existing boiler integrity while integrating modern combustion controls. The selective catalytic reduction addition ensures compliance with evolving air quality norms, minimizing environmental impact.

EVNGENCO2’s strategy emphasizes reliability and sustainability, leveraging proven OEM partnerships to minimize downtime during upgrades. Site-specific modifications will optimize performance under local operating conditions, including high humidity and temperature variations.

The neighboring O Mon 4 project complements this effort by introducing high-efficiency gas turbines, capable of rapid load response to balance renewable integration. Together, these developments strengthen grid stability amid growing demand.

Mitsubishi Power’s regional presence facilitates knowledge transfer, with training programs for local engineers enhancing operational autonomy. Long-term service agreements will sustain equipment performance over the plant lifecycle.

Vietnam’s power sector continues prioritizing cleaner fuels to meet expansion goals while addressing emission targets. The O Mon initiatives exemplify collaborative approaches between international technology providers and national utilities, delivering scalable solutions for energy transition. By upgrading legacy assets and deploying advanced systems, the projects contribute to efficient, lower-carbon generation in a key economic zone.