The deployment is expected to cut approximately 60,000 tonnes of carbon emissions annually, with the potential for a tenfold increase as the technology is scaled. The RDH system will be powered entirely by renewable energy from Adani Cement’s own portfolio, ensuring zero-emission industrial heat. The project demonstrates the practical feasibility of clean, electrified industrial heat powered by renewables and reinforces India’s potential as a global hub for low-carbon cement manufacturing.

Vinod Bahety, CEO of Adani Group’s Cement Business, said: “The world’s first commercial deployment of Coolbrook’s RotoDynamic Heater within our operations marks a pivotal moment in our decarbonisation journey. This is a major leap towards achieving our net-zero goals. By integrating such cutting-edge electrification solutions into our cement production, we are accelerating the shift away from fossil fuels and setting a new standard for low-carbon cement manufacturing.”

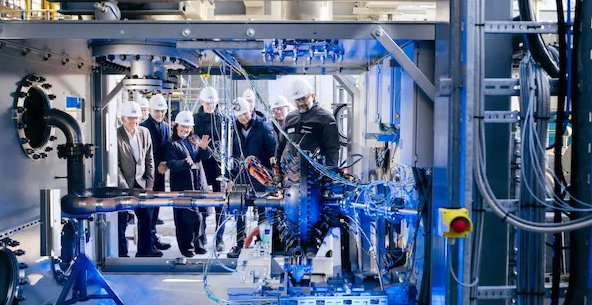

Joonas Rauramo, CEO of Coolbrook, added: “Entering into the first industrial-scale project in the world with Adani Cement marks a transformative step for industrial electrification in one of the world’s most vital cement markets. Our mission is to make RotoDynamic Technology a new industry standard for decarbonising hard-to-abate sectors.”

The collaboration includes plans to expand RotoDynamic Technology across other Adani Cement facilities, targeting at least five additional projects within two years. The first-generation RDH will deliver hot gases at approximately 1,000°C, enhancing the drying process and the efficiency of alternative fuels.

Adani Cement aims to increase its use of alternative fuels and resources to 30 per cent and green power to 60 per cent by FY2028. These measures are part of the company’s broader SBTi-validated strategy to achieve net-zero emissions by 2050, positioning the Boyareddypalli project as a key milestone in India’s transition toward sustainable cement production.

By demonstrating industrial-scale clean electrification, Adani Cement and Coolbrook are setting a precedent for the cement sector, showcasing how advanced technology and renewable energy can work together to achieve substantial emission reductions while maintaining operational efficiency.