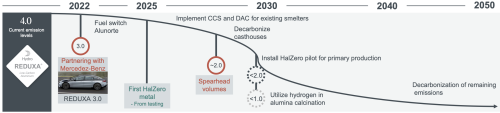

Mercedes-Benz will collaborate with Norwegian aluminum producer Hydro to reduce significantly the CO? footprint of aluminum in the automotive supply chain. Hydro and Mercedes-Benz will from 2023 to 2030 collaborate on a joint technology roadmap aiming to develop aluminium solutions approved for automotive applications with a CO2 footprint below 3.0 kgCO2/kgAl. The ambition is to approach near-zero aluminum by end of the same time period.

Hydro will deliver its first volumes of aluminum with a carbon footprint below 3.0 kgCO2e/kgAl—Hydro REDUXA 3.0—to Mercedes-Benz in 2023. The product will be introduced to a range of Mercedes-Benz models including the electric EQ models.

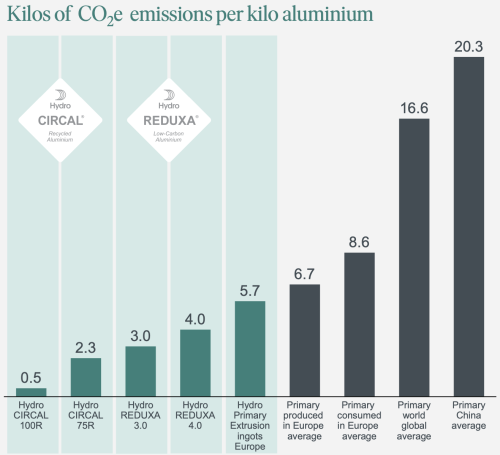

Hydro is working on two specific low-carbon lines: REDUXA (primary production) and CIRCAL (recycled aluminum). Hydro is currently delivering REDUXA 4.0—aluminum with a maximum 4.0 kg CO2 per kgAl (including all process steps). Source: Hydro.

Hydro already supplies Mercedes-Benz with CO?-reduced aluminum for its foundry in Stuttgart Mettingen. The strategic partnership raises the cooperation to a new level to optimize decarbonization processes for aluminum used in vehicle manufacturing.

Mercedes-Benz and Hydro are not only looking into further reduction of emissions but also aim to reduce the use of primary resources through increased use of secondary materials from post-consumer scrap.

Together with steel, aluminum is proportionally the most widely used material in many vehicles. Therefore, this agreement marks a step for the supply of low emission aluminum and thereby reducing the carbon footprint of Mercedes-Benz products.

For realizing the path towards near zero CO? aluminum it is important to optimize both the primary aluminum production process, starting with CO?-optimized aluminum oxide production, as well as reducing the CO? emissions resulting from the electrolysis process.

At the same time, next to technological improvements, increasing the use of recycling material plays a major role for realizing further CO? reductions. Producing aluminum by using secondary material only requires 5% of the energy compared to aluminum production based on primary resources. As part of the collaboration Mercedes-Benz and Hydro even want to take it one step further by exploring solutions how to implement a closed-loop-recycling.

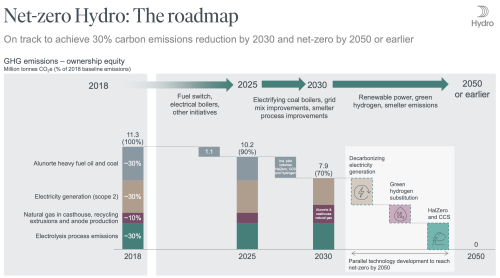

Hydro is well positioned to be a low-carbon producer, as 70% of the electricity used in Hydro’s primary production is based on renewable power.