Power plant owners and operators have a range of systems available to help reduce pollutants at their facilities, depending on a number of factors. And industry experts agree—there is no “one size fits all” when it comes to making a choice.

Environmental regulations designed to curb emissions from power plants have led to development of a range of technologies to control pollutants. These technologies have evolved as regulations have changed, and as more pollutants have been identified.

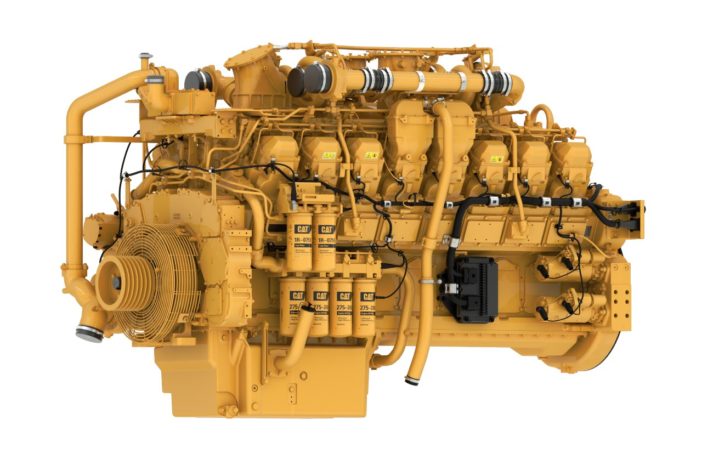

Recent moves by the Environmental Protection Agency (EPA) to relax some of the rules surrounding coal combustion residuals and wastewater from power plants may impact how quickly some pollution controls are adopted. But industry experts who spoke with POWER said those rollbacks are not likely to slow the pace of technology advancements designed to lessen the environmental impact of power generation (Figure 1), particularly from coal-fired units, the major source of pollutants such as sulfur oxides (SOx), carbon dioxide (CO2), heavy metals such as mercury, and particulate matter (PM), which includes acids (such as nitrates and sulfates), organic chemicals, metals, and soil or dust particles.

Suzette M. Puski, business development manager with Babcock Power Environmental (BPE), a division of Babcock Power, told POWER that the EPA’s Affordable Clean Energy (ACE) rule lists several technology options for controlling pollutants, including such things as rebuilding or replacing boiler feed pumps, steam turbine blade path upgrades, and utilizing industry-best operations and maintenance practices.

“It’s important to look at the whole picture and not just focus on one aspect of the plant,” Puski said. “It is important to engage plant personnel who cover generation, air quality control, operations, and maintenance to understand the impact of a technology across the plant.”

BPE is known as a leader in selective catalytic reduction (SCR), which focuses on reducing emissions of nitrogen oxides (NOx). The company also provides wet scrubber technology, which helps achieve reductions in SO2, along with dry flue gas desulfurization systems for controlling acid gases. BPE also has advanced technologies for controlling emissions of mercury. Puski said technology is important for emissions reduction, but noted plant operators should look at other procedures to optimize performance.

“For example, detune low-NOx burners and rely on downstream SCR to control NOx emissions to reduce LOI [loss on ignition] and improve boiler maintenance and ash marketability,” Puski said. “Double-check your assumptions. You might find out you have problems you took for granted could not be resolved when in fact that is not true. It also is important to recognize where the unit is going to operate to target how efficiency can be improved for specific run conditions. How the system was tuned at full load may not be efficient at reduced loads or with current fuel mixes.”

‘Not as Easy as It Seems’

“There are a lot of technologies out there, but [some are] only applicable to [an individual] plant, not other plants,” said Joe Riley, president of Hopewell, New Jersey-based STM Ecosystems Inc. “There’s no holistic look at this thing, which is really where multi-pollutant [technology] comes in, where you can produce a good result. Unfortunately, it’s not as easy as it seems.”

Riley talked with POWER about both traditional and “more complex” methods of pollutant control. “We might do some injection of urea in the boiler for SNCR [selective non-catalytic reduction]. Activated urea can do some pretty cool stuff,” he said. SNCR can be used for NOx emission control on industrial boilers, electric utility steam generators, thermal incinerators, and municipal solid waste energy recovery facilities.

“You can inject lime in the boiler, or sodium bicarbonate, so that they react on the filter surface,” Riley said. Sodium bicarbonate, or baking soda, is an alkaline reagent for dry flue gas treatment. Projects over the past few years have shown it has advantages over lime in flue gas cleaning. Some talk of sodium bicarbonate refers to trona, a naturally occurring mineral becoming more widely used for air pollution control. Trona effectively removes acid gases such as sulfur oxides (SO2 and SO3) along with hydrochloric acid (HCl) and hydrofluoric acid (HF) from flue gas.

Riley said STM Ecosystems was instrumental in developing dry sodium bicarbonate scrubbing technology and supplied a sodium bicarbonate milling system for one of the world’s first dry sorbent injection systems. He noted that scrubbers “all have different results for different pollutants,” often depending on the additive in the system. Wet scrubbers use a liquid to remove pollutants from a contaminated gas stream via absorption. Water is used most often, though it’s common to include a chemical additive in the water so that the pollutants undergo a reaction and are converted to a less-hazardous compound. The most common chemical is sodium hydroxide (NaOH), which is also known as caustic soda. Because it is a strong base, caustic is an excellent scrubbing agent to remove acid gases, including HCl and SO2, and can also be used with hydrogen sulfide (H2S), mercaptans, and certain organic macromolecules such as fatty acids. Some facilities use water alone and forgo the use of chemical reagents.

“It’s a trial-and-error kind of thing,” Riley said. “It works in one case, and then you have to try to understand why it doesn’t work in another. For example, when a lot of people talk about multi-pollutants, they look at the additives. They have sodium bicarbonate impregnated with ammonia, they put that in front of an SCR, and the ammonia addresses the NOx, and the sodium bicarbonate addresses the acid gases that can plug the SCR.”

Software Plays a Role

Ron Beck, director of industry marketing for Oil and Gas at Bedford, Massachusetts-based AspenTech, told POWER, “When thinking about pollution control technology in power generation, many generators think first about hardware solutions to increase removal of pollutants or adjust the basic power conversion process. With the increase in scope of optimization, analytics, and digital twin monitoring technology, software technology approaches can complement or even replace costly CAPEX [capital expenditure] investments in achieving compliance and sustainability goals.”

Beck said there are technologies that can improve combustion efficiency and a power plant’s generation capacity, while also cutting emissions. “One interesting approach, known well to industrial cogeneration giants, is advanced process control,” he said. “For example, the world’s largest non-utility power producer engaged a systematic program to pair advanced process control with digital twin modeling in their global network of cogeneration facilities. Advanced process control controls combustion, cooling, and other processes much more closely than conventional controls, enabling the operator to run the combustion units, turbines, and related systems with much lower variability and much closer to design specifications.

“In this case, they found a significant increase in generation capacity, better prediction of generating loads, and reduced emissions and wastes, again due to the reduction in variability. This enabled them to predict power generation much more accurately, allowing them to feel confident selling excess capacity to the grid without risk of creating shortfalls in their own demand. Advanced process control therefore can help power operators to run their plants to achieve precise emissions goals and to manage thermal efficiencies better.”

Carbon Capture

A pilot project for carbon capture technology is underway at the Drax Power Station in the UK (Figure 2). The project is known as bioenergy carbon capture and storage (BECCS), and is designed to show that the proprietary solvent developed by C-Capture—part of the chemistry department at the University of Leeds—can be used to isolate the carbon dioxide from the flue gases released when biomass is used to generate electricity. The goal is to make Drax, near Selby in North Yorkshire, the world’s first negative emissions power station. The project is capturing a metric ton of CO2 daily. The pilot, commissioned in November 2018, marks the first time CO2 has been captured from combustion of a 100% biomass feedstock.

Drax has invested £400,000 ($515,000) in the project. Officials have said it could be the first of several projects at the power station to deliver a rapid, lower-cost demonstration of BECCS.

Caspar Schoolderman, director of engineering at C-Capture, said of the project: “Working at this scale is really where the engineering gets interesting. The challenge now is to get all the information we need to design and build a capture plant 10,000 times bigger. It’s only really when we get to those sorts of scales that we can start to have an impact on the climate.”

Brad Crabtree, vice president of carbon management for Minneapolis, Minnesota-based Great Plains Institute, highlighted the Allam cycle technology from Durham, North Carolina-based Net Power, as an example of a system that could bring transformative change to the power generation industry. The Allam cycle, according to Net Power, “uses a high-pressure, highly recuperative, oxyfuel, supercritical CO2 cycle that makes emission capture a part of the core power generation process, rather than an afterthought. The result is high-efficiency power generation that inherently produces a pipeline-quality CO2 byproduct at no additional cost to the system’s performance.”

Said Crabtree: “I think Allam cycle has the potential to be a game-changer. It’s still to be borne out, but if the cost reductions and the efficiency gains they’re proposing can be proven, that could be pretty transformational in the power sector.” He added: “It’s encouraging that large companies [he pointed to Occidental Petroleum as an example] are making investments in that technology.”