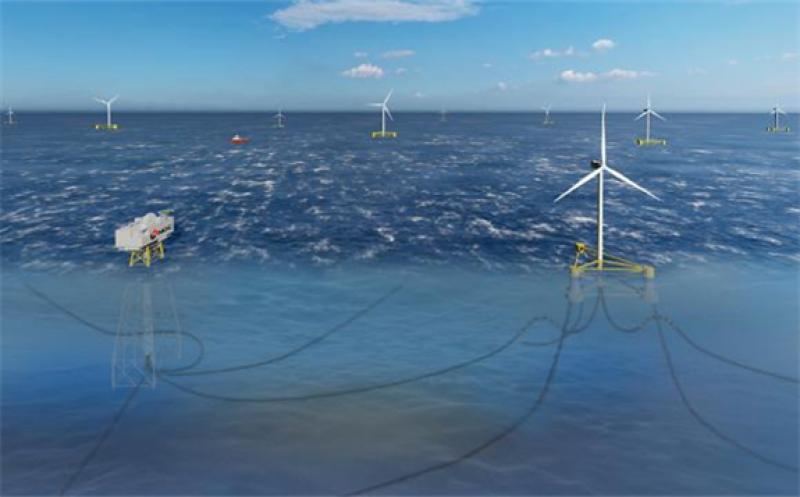

OceanX, the world’s largest single capacity floating wind power platform, embarked on its journey from Guangzhou to the Yangjiang Mingyang Qingzhou IV offshore wind farm in Guangdong, China. After a 191-nautical-mile, over 50-hour tow, the platform’s arrival marks the commencement of a new era in green energy, poised to set the standard for offshore wind power technology.

Developed by Mingyang Group, this floating wind turbine platform is arranged in a ‘V’ shape and carries two 8.3 MW offshore wind turbines. With a total capacity of 16.6 MW, it can be used in a wide range of sea areas around the world with water depth of more than 35 m.

OceanX impeller reaches 219 m at its highest point and a maximum width of about 369 m in the air. The whole wind turbine platform has a total displacement of 15 000 t, and a towing draft of 5.5 m. Once operational, it is expected to produce 54 million kWh annually, enough to power 30 000 three-person households for a year.

OceanX advances wind turbine innovation by enhancing core component technology, driving both aesthetic and functional refinement in design and manufacturing.

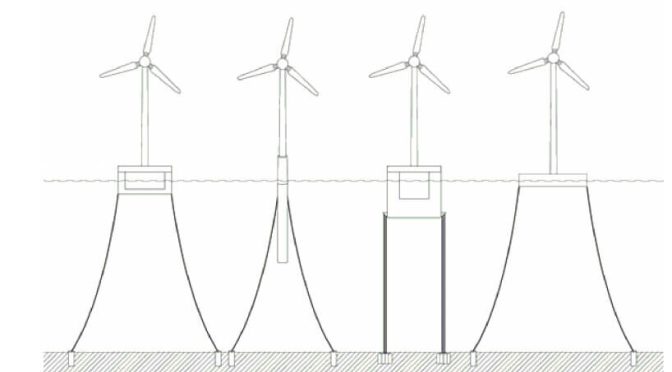

Floating foundation is the key component for floating wind turbines in the deep and distant sea. Unlike traditional steel floating foundations, OceanX’s floating foundation consists of three floats, concrete arms and connectors.

It pioneers the use of ultra-high performance concrete with a compressive strength exceeding 115 MPa for floating foundation construction, a material four times stronger than standard concrete, significantly enhancing load-bearing capacity. The floating foundation also utilises a pre-stressed high-strength concrete assembly structure, facilitating modular and batched manufacturing, thereby substantially reducing construction costs.

Mingyang has leveraged caisson pre-tensioning technology in its precast concrete construction, emphasising interface sealing and the precision of the pre-stressing process. With 1500 steel strands expertly threaded through the floating body’s arm, it has meticulously controlled tensioning forces and ensured uniform stress across the end face throughout the construction.

OceanX also introduces a cutting-edge float design, using layered material to replace traditional steel or hybrid materials. The float lightens the floats and accommodates their curved form. The three streamlined ellipsoidal floats offer reduced wave resistance and enable lateral rotation, providing yawing power. Rigorous testing confirms that the streamlined shape strikes an ideal balance between stability and load-bearing.

Notably, housing two wind turbines on a single floating platform can significantly cut down the per-kilowatt cost, as well as reduce the required sea area and operational maintenance expenses.

OceanX, with its robust floating foundation, features the integration of two towers in a ‘V’ configuration, marking a first for offshore wind platforms.

OceanX’s tower, with its elongated elliptical design, maximises wind exposure along its longer axis, significantly exceeding that on the shorter axis. By aligning the tower with the wind direction at an optimal angle, the wind platform’s area is effectively increased, allowing for swifter alignment to the wind and boosting the efficiency of wind energy capture. Additionally, the towers are fitted with a dual-access system for lifts and ladders, ensuring the comfort and safety of personnel during ascent and descent.

In addition to the evolution of the wind turbine form, Mingyang also expands the boundaries of the application of the cable-stayed system, installing it for the first time globally in a wind turbine.

OceanX has harnessed the spatial framework of its tower system, integrating the world’s largest high-stress strand cable-stayed system. A robust network of 13 main and six auxiliary cables efficiently tensions the mainframe, tower, and floating foundation, establishing a stable tensioning mechanism across the wind turbine’s components. This innovative cable-stayed design has redefined the load transfer path of traditional wind turbines. Instead of the tower bearing the full impeller and gravity loads, the system distributes the tower’s gravity load to the tension cables, with the tower now only partially supporting the impeller loads. This strategic redistribution significantly lightens the tower’s load, enabling a streamlined and lightweight structural design.

To seamlessly integrate the 200-m-long, 18 cm dia. cables between the wind turbine, tower, and floats, OceanX employs a precise combination of graded pre-tensioning, multi-dimensional monitoring, and synchronised tensioning. This ensures that all 13 main cables achieve their individual pre-tensioning specifications and can be pre-tensioned to a maximum force of 350 t, optimising the structural integrity and performance of the wind turbine system.

On the V-shaped tower, two main engines are equipped with parallel impellers, covering a sweeping area exceeding 52 000 m2 – comparable to the size of seven standard football fields. With the impeller blades’ tips a mere 5 m apart, this pioneering design optimises impeller pitch and wind efficiency while leveraging the V-shape of the tower. It ensures impeller safety and enhances both wind capture and structural stability.

Upon start-up, the impellers rotate in opposite directions, enhancing wind speed in the central area and boosting electricity generation from air kinetic energy by 4.29% compared to a single, large turbine with an equivalent swept area.

In the context of the entire wind farm, longer blades on a single turbine can significantly affect the turbine downstream. OceanX employs two small-sized wind turbines, leveraging the coupled vortex effect from counter-rotation to mitigate efficiency losses across the farm.

OceanX utilises a downwind design, alleviating tower headroom constraints for the blades, allowing greater movement, and enhancing the unit’s power generation efficiency through flexible and efficient wind energy capture.

In the face of extreme typhoon conditions, floating wind turbines must be de-signed to withstand 360° typhoon loads from the outset to ensure stability and safety. OceanX employs a single-point mooring system, which allows the platform to adaptively yaw with the typhoon’s direction. This ensures that the wind turbine consistently faces the incoming wind, regardless of the typhoon’s path.

In the mooring system, to withstand forces equivalent to a level 17 typhoon, the turret’s high-precision slewing bearings must offer exceptional load-bearing capacity and superior underwater sealing. To guarantee OceanX’s stable maritime operation, Mingyang has meticulously assembled the turret system, adhering to stringent standards and precision demands.

Data reveals that the single-point mooring solution reduces the ultimate load on the support structure by 40%, significantly improving the wind turbine’s safety and stability in typhoon conditions. This technology’s implementation boosts the standardisation and efficiency of onshore operations for marine and engineering equipment.

OceanX is also capable of managing total health of the turbine to optimising power generation efficiency and lowering the maintenance cost thus finally cut down levelized cost of energy (LCOE) under different environmental conditions.

In April 2020, the 1:10 scale prototype of the OceanX dual-rotor floating wind turbine platform was launched in Lake Quarry, Germany. By October, it had completed a two-month offshore operation in the Baltic Sea, enduring tests equivalent to 72 m/sec. winds and 30-m waves, and earned a feasibility certificate from DNV.