Project Background: Geothermal as a Business Strategy

As reported a few months ago, Steam has been chosen by Karsan & Sons’ (KRSL) for their NDOVU NAKURU Cement project in Kenya’s Menengai field.

KRSL is a multi-generational family business operating in the aggregate and cement sectors. Ndovu Cement, KRSL’s cement brand, ranks seventh in terms of market share in Kenya and has a production capacity of 1200 tonnes per day. It currently has six quarries in Kenya and one cement grinding plant with two grinding mills south of Nairobi in Athi River.

The NDOVU NAKURU project plans to establish a second grinding plant north of Nairobi, which will expand KRSL’s market base and—crucially—align with its 10-year objective of using renewable energy for all new operations and facilities.

Beyond its value as a sustainable energy source, KRSL chose geothermal because it is reliable. Power outages, which are not uncommon in Kenya, can damage the equipment used in cement production. Even if they don’t cause immediate damage, however, frequent cold restarts can weigh heavily on cement producers’ operational costs.

Dr. George Muia, KRSL’s Head of Energy Investments, explained the firm’s vision for the Nakuru project, and how it fits into its strategic plan. “One of KRSL’s strategic objectives is to reduce its carbon footprint by 40% in 10 years. We have already reduced the number of diesel vehicles in our aggregate quarries by over 50% and in turn introduced electric conveyor systems in two of our largest quarries. Geothermal provides us the opportunity to continue pursuing our objective of lowering our carbon footprint as much as possible, while also growing more competitive as business.”

Project Overview

The importance of the project may be easy to understate. Despite being the world’s first direct-use geothermal project in the cement industry, it involves just one 4-MW ORC power plant and one geothermal heat-powered dryer. It does not have the technological fanfare associated with emerging technologies like Enhanced Geothermal Systems (EGS) and Advanced Geothermal Systems (AGS) and pales in comparison to the 1 GW installed geothermal power generation capacity that Kenya is aspiring to achieve very soon.

However, small-impact projects like Karsan’s are essential for educating both the public and policy makers on how innovative applications of geothermal energy can diversify the tools for accelerating the energy transition. By illustrating the surprising Use Cases and benefits of geothermal energy, the Karsan project inspires broader support for such initiatives and emphasizes the role that companies working in traditionally hard-to-decarbonize sectors can play in finding solutions on their collective journey towards a sustainable economy.

The Karsan Project in Detail

The Karsan cement plant is in the Menengai steamfield, about 6 kilometers away from Geothermal Development Company’s (GDC) production well MW-18A. Karsan’s current facilities include a cement grinding factory and aggregate quarry, and the next step in the company’s roadmap is to produce its own pozzolanic tuffaceous ash, a much less energy-intensive material which can be used to reduce the amount of clinker needed in concrete production.

To this end, Steam is currently building concept and basic designs for the direct application of heat from the geothermal brine in Karsan’s cement plant’s drying unit, where the pozzolanic tuffaceous ash will be processed.

From well MW-18A, a two-phase flow is discharged and sent to steam/brine separator. After separation, the brine will be sent to the drying system through an aqueduct of about 150 meters through a booster pump after the separation, and the steam will be sent to a power plant through an approx. 100 m steam pipeline.

The exact reduction in carbon emissions that Karsan will achieve through this project depends on several factors, including the percentage of clinker that the pozzolanic tuffaceous ash will replace in the cement production process and the production capacity of the dryer itself. However, a recent study concluded that emissions reductions of up to 20% can be achieved by utilizing pozzolanic materials in cement production.[1]

Geothermal: Industrial-grade Renewable Energy

Cement manufacturing is responsible for roughly 8% of global carbon emissions, and that number is rising. Large consumers like China, which used more concrete between 2011 and 2013 that the US did in the entire 20th century, are driving the market’s growth. Cement’s carbon intensive nature is largely due to the production of “clinker”, the substance which gives concrete its “strength”, and which accounts for over 90% of cement’s carbon emissions.[2]

Clinker is produced primarily by heating limestone in a kiln at around 1500°C, which causes the limestone (calcium carbonate) to decompose into calcium oxide (lime) and CO2. The CO2 is then traditionally released into the atmosphere. To reach 1500°C, however, cement manufacturers need sources of electricity that are both robust and reliable. Intermittent renewables like solar and wind are typically too risky, both in terms of their ability to provide electrical “baseload” (i.e. non-intermittent) power and in terms of electrical capacity, for cement plant owners to justify as low-carbon electricity sources.

Typically, cement manufacturing plants must either install a fossil fuel powered generator on-site or purchase electricity off the grid, or both. But with 60% of global electricity production still coming from fossil fuels—particularly from coal, which accounted for roughly 36% of global electricity production in 2023[3]—choosing the non-intermittent (“baseload”) power of geothermal is a strategic solution for companies who have both the goal of building a sustainable business and the goal of improving their own energy security.

Karsan, Menengai, GDC and the Emergence of a Kenyan National Geothermal Strategy

To understand fully the circumstances around Karsan’s ability to deliver this innovative project, its important to understand how the Menengai field is being developed.

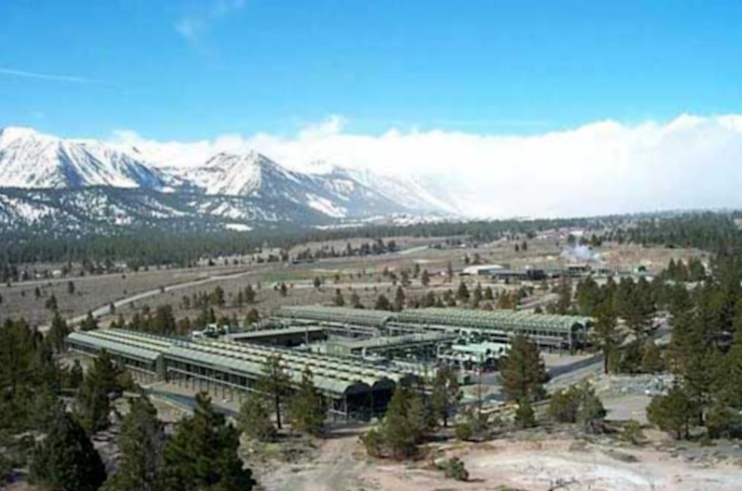

The Menengai Caldera, located in Nakuru County, is one of Kenya’s significant geothermal resources with a potential capacity of up to 1.6 GW. The first phase of the Menengai project includes three power plants, each with a capacity of 35 MW, providing a combined output of 105 MW[4][5]. One of these, the Sosian Menengai power station, is another of Steam’s Owner’s Engineering assignments.

At Menengai, state-owned GDC undertakes the drilling of geothermal wells in order to protect potential developers from the high financial risks associated with drilling. Upon achieving a productive well, GDC then also engineers the construction of steam gathering systems. The steam from these systems is then sold to independent power producers (IPPs) who then convert the steam purely into electricity or who develop combined heat and power projects like the Karsan project, using the heat directly.

But Kenya, through GDC, has larger plans in mind. The state envisions at Menengai a geothermal-powered industrial park which aims to utilize both geothermal heat and power. This initiative includes various direct-use applications of geothermal energy such as milk pasteurization, greenhouse heating, aquaculture, laundromats, and grain drying[6]. The industrial park is expected to attract numerous businesses due to the lower power rates and the reliable supply of geothermal steam.

As such, the Karsan project is one of the state-run development’s pilot projects in the future Menengai industrial park. It also an important project within the scope of Kenya’s broader Vision 2030 development plan, which aims to increase electricity generation capacity and promote renewable energy sources. This ultimately supports Kenya’s goal of reducing greenhouse gas emissions and ensuring a sustainable and secure energy future. In the case of Menengai, this means leveraging geothermal energy to enhance energy security, lower electricity costs, and attract industrial investments.[7][8]

[1] https://www.sciencedirect.com/science/article/pii/S2772397624000261

[2] https://energypost.eu/concrete-8-of-global-emissions-and-rising-which-innovations-can-achieve-net-zero-by-2050/

[3] https://www.reuters.com/markets/commodities/fossil-fuels-still-dominate-global-power-systems-2023-11-30/

[4] https://www.power-technology.com/projects/menengai-geothermal-power-project-kenya/

[5] https://constructionreviewonline.com/construction-projects/menengai-geothermal-power-plant-project-in-nakuru-kenya/

[6] https://www.thinkgeoenergy.com/gdc-planning-geothermal-industrial-park-at-menengai-kenya/

[7] https://constructionreviewonline.com/construction-projects/menengai-geothermal-power-plant-project-in-nakuru-kenya/

[8] https://www.thinkgeoenergy.com/35-mw-menengai-geothermal-power-plant-kenya-starts-grid-supply/