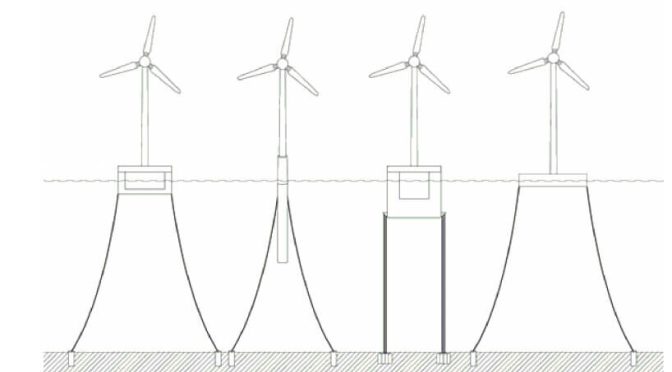

The RFI is structured in three distinct packages, each designed for specific facility types: standard offshore steel shops, tubular/jacket yards, and monopile/tower facilities. Aikido Technologies stated: “This is how we can build 1, 50 or 100 of these units with existing fabrication capabilities, with components that can be easily transported around the world for final assembly at a local port. No need for custom yards, custom vessels or custom ports.”

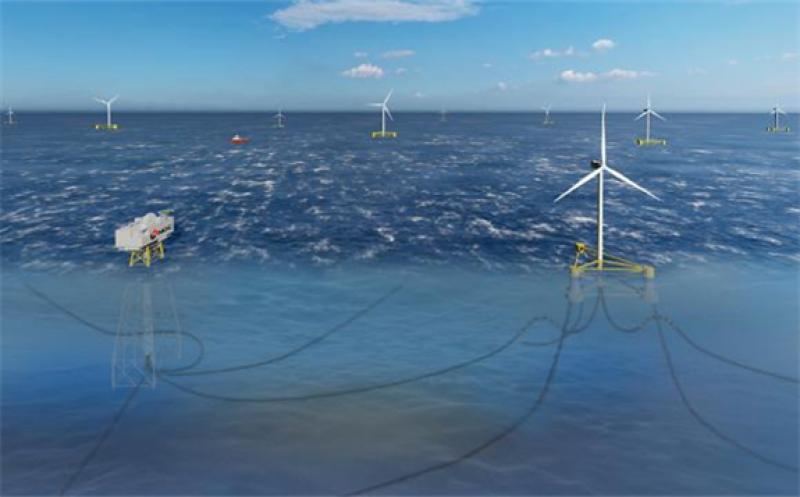

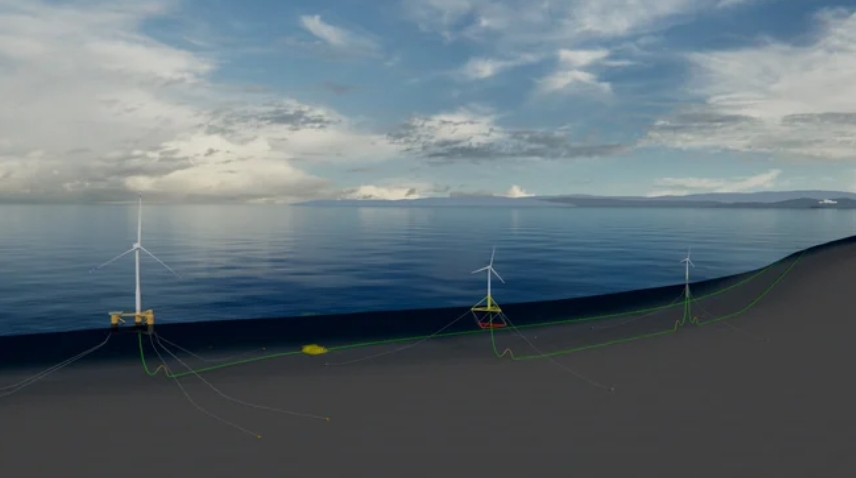

In May 2025, Aikido secured a slot at the Marine Energy Test Centre (METCentre) in Norway for its AO60 platform, set to be a pioneering 15 MW demonstration project. Scheduled for installation in 2027, the platform is expected to be among the largest floating wind structures deployed, according to METCentre.

The AO60 platform comprises thirteen modular steel components, including columns and trusses, which can be manufactured at existing offshore wind or steel fabrication sites. These components will be transported to a final assembly site near the Norwegian test center, where the platform can be completed in days, streamlining construction compared to traditional methods.

Earlier this year, the American Bureau of Shipping (ABS) granted a statement of maturity for Aikido’s floating wind platform, marking a significant step in its technology qualification process. This recognition underscores the platform’s readiness for deployment and its potential to advance offshore wind energy.

The AO60 project supports the growth of renewable energy by utilizing existing infrastructure, reducing the need for specialized facilities. Aikido’s modular design enhances efficiency, enabling scalable production and assembly to meet global demand for floating wind solutions. The initiative positions Norway as a key testing ground for innovative offshore wind technology, contributing to sustainable energy development.