The foundation of the cooling tower was completed in November 2023, when the final concrete was poured. The circular base measures more than 10 metres in width and over 2 metres in thickness. Approximately 15,900 cubic metres of concrete were used for the foundation.

The cooling tower now stands 218.7 metres tall, with a base diameter of about 175 metres. Its construction required a total of 137,400 cubic metres of concrete. The water spraying section covers an area of 20,000 square metres. The tower consists of a foundation, inclined pillars, tower tube, and inlet, as well as a central water shaft, distribution system, heat exchange filler, water collection system, main tank, and water eliminator.

SPIC confirmed that with the main structure completed, the installation of internal components is scheduled to begin. The company said: “The successful completion of the cooling tower has accumulated valuable experience for the design and construction of ultra-large seawater cooling towers in China’s nuclear power field.”

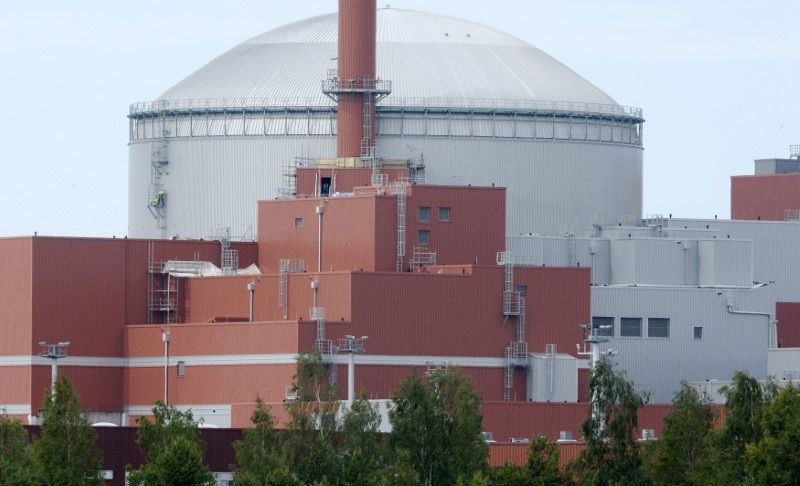

Unlike the once-through cooling system widely used in conventional nuclear power plants, Lianjiang Unit 1 employs secondary circulation cooling technology. This approach replaces direct seawater intake and discharge with recycled cooling water, using the atmosphere as the ultimate heat sink through air-water heat exchange. SPIC described it as “a new technological breakthrough” for China’s nuclear sector.

The company added: “This significantly reduces water intake, greatly minimising the operational risk of marine organism infestation at the nuclear power plant and enhancing the safety and stability of power supply. Furthermore, water discharge is significantly reduced to one-fortieth of that of traditional nuclear power plants, and the discharge temperature approaches that of natural seawater, further enhancing the environmental friendliness of the nuclear power project.”

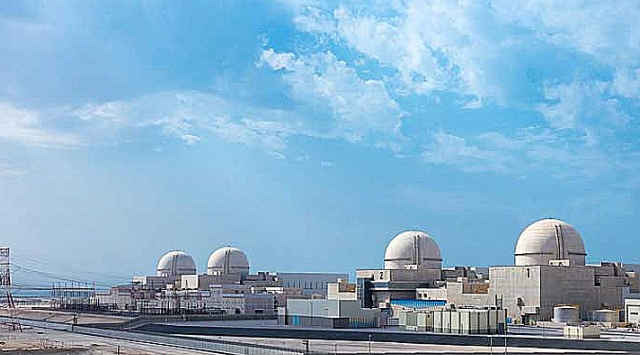

The first phase of the Lianjiang nuclear power project, SPIC’s initial coastal nuclear project in Guangdong, includes two CAP1000 reactors. The site is planned to eventually accommodate six such units. It is the first nuclear facility in China to implement seawater secondary circulation cooling technology and the first to build a super-large cooling tower of this kind.

Construction of the first two CAP1000 reactors—China’s version of the Westinghouse AP1000, each with a capacity of 1250 MWe—was approved by the State Council in September 2022. Excavation works began immediately, and the first safety-related concrete was poured for Unit 1 in September 2023, followed by Unit 2 in April 2024.

Lianjiang Unit 1 is expected to be completed and enter commercial operation in 2028, strengthening China’s nuclear power development and contributing to cleaner energy supply.