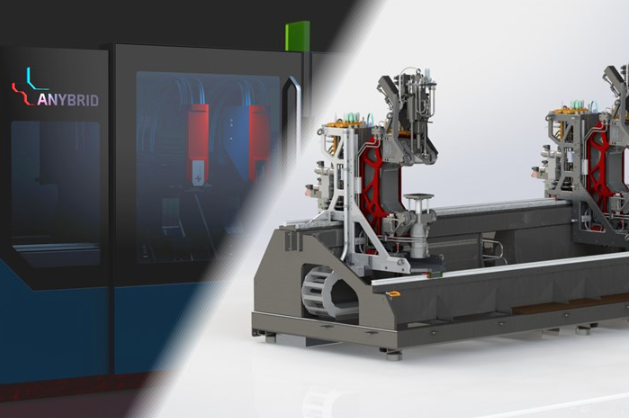

The Rav·In system combines high variability with productivity, enabling automated, high-mix, high-volume manufacturing scenarios. By incorporating lightweight materials, it achieves precise and rapid movements along the production axis within a single, streamlined system. The design, featuring multiple C-frames, supports scalability and seamless integration into automated production lines.

“We are breaking down traditional ways of thinking in plastics processing, where injection molding and extrusion were previously strictly separated,” said Michael Stegelmann, managing director and co-founder of Anybrid GmbH. “Rav·In is also an integral part of automation and can be easily scaled up for production thanks to its design with multiple C-frames.” This approach allows manufacturers to produce complex components with greater speed and design flexibility.

Since its establishment in 2020, Anybrid has focused on pioneering mobile injection molding solutions for industries such as automotive, electronics, and industrial manufacturing. The Rav·In system builds on this mission, enabling global customers to create intricate products more efficiently while maintaining high precision. The technology supports diverse applications, enhancing production capabilities across various sectors.

Anybrid’s innovative system is expected to streamline manufacturing processes by combining the benefits of continuous production with injection molding’s precision. This advancement reduces production times and costs while supporting sustainable practices through efficient material use. The Rav·In system positions Anybrid as a leader in flexible, high-performance manufacturing solutions, contributing to Dresden’s reputation as a hub for industrial innovation.