Pennsylvania’s steel industry has the potential to lead a national transition to reduce or even eliminate carbon emissions if it switched to making so-called green steel, according to a report issued Monday by the Ohio River Valley Institute, a nonprofit research group.

Pennsylvania’s steel industry has the potential to lead a national transition to reduce or even eliminate carbon emissions if it switched to making so-called green steel, according to a report issued Monday by the Ohio River Valley Institute, a nonprofit research group.Southwest Pennsylvania, where the industry is concentrated, has the water and wind resources, as well as a long history of steel making, that would enable it to change from emissions-heavy coal as the fuel for making steel, to hydrogen, which can be used to convert iron to crude steel in an electric arc furnace. If the electricity that powers the furnace comes from a renewable source, the resulting steel would be almost free of carbon emissions, the report said.

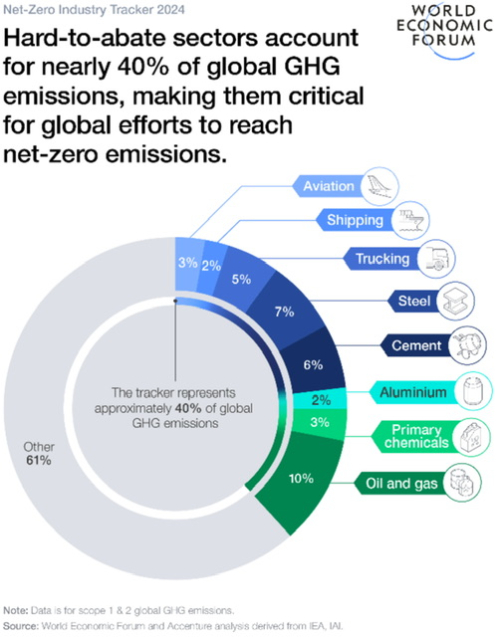

Wide-scale adoption of “green steel” manufacturing for primary steel, already being pursued by leading steelmakers in Spain, Germany and Sweden, would reduce the emissions of an industry that is responsible for 7 percent of global greenhouse gases, and almost a quarter of the world’s industrial emissions, said the report, titled “Green Steel in the Ohio River Valley.”

Nick Messenger, a co-author, said during a press conference that challenges to the adoption of green steel include a current regional shortage of renewable power.

But a decision by the industry to adopt green steel could stimulate the growth of wind and solar in Pennsylvania and nearby, he said. “This kind of pathway would provide an opportunity to build up a much larger wind and solar capacity in the region,” he said.

Pennsylvania generates more electricity than all but two states, Texas and Florida, and it ranks just ahead of California, according to 2022 figures from the Energy Information Administration. The state gets more than half of its electricity from gas-fired power plants, about one-third from nuclear, and about one-tenth from coal. Wind and solar are far behind, with 1.6 percent for wind and 0.1 percent for utility-scale solar. For perspective, Pennsylvania’s share of wind and solar ranks 43rd in the country.

Green steel would help meet a target set by the International Energy Agency of reducing the industry’s carbon emissions by 50 percent by 2050 to meet the global climate goal of limiting the rise in global temperatures to 1.5 degrees Celsius from pre-industrial levels.

When so-called green hydrogen is produced from renewable sources via the electrolysis of water, the resulting “green steel” is virtually emissions-free.

By contrast, in a conventional blast furnace, coke is combusted at a very high temperature—near 2,000 degrees Celsius—which melts iron ore and produces carbon dioxide. But a process called Direct Reduction of Iron (DRI) can use hydrogen as a “reducing agent” to remove oxygen from the iron, producing only water, not CO2. The hydrogen technique also operates at a much lower temperature—about 1,000 degrees Celsius—which also requires less energy.

“For generations, the steel industry has shaped the economy and culture of the Ohio River Valley; now, fossil fuel-free steel produced with green hydrogen-based direct reduction offers the region a unique opportunity to reshape the local economy and become a global leader once again,” the report said.

It argued that adoption of green steel production would have positive economic effects on a region where steel-industry employment has already fallen, and which is expected to decline further if it continues to do “business as usual.”

Steel industry jobs would fall by about 30 percent by 2031 without a change to “green steel” manufacturing, the report said, but regional jobs would grow by 27 to 43 percent if the industry invests in fossil-free hydrogen production using wind and solar in the region. In Pennsylvania, the steel industry and allied manufacturing supported about 9,600 direct jobs in 2021, down some 28 percent from 2011, reflecting the continued shift of jobs overseas, especially to China, which now produces about half of the world’s steel.

The paper predicted that a switch to green steel production could create 458 direct jobs and as many as 2,200 indirect jobs in the region, while a business-as-usual approach would result in losses of 328 direct and up to 2,700 indirect jobs.

Outside the United States, there is increased investment and development in hydrogen-based DRI steel. In 2022, a venture between a Swedish steel producer and a Finnish iron-ore supplier delivered the world’s first commercial fossil-fuel free steel to Volvo group. The Swedish partner, SSAB, expects to deliver commercial quantities of the steel to its customers starting in 2026. Several other European steelmakers including Germany’s ThyssenKrupp and Spain’s ArcelorMittal plan the same by that year. In Asia, Korea’s POSCO is planning to test hydrogen-based steelmaking by 2028.

“The U.S. is clearly behind,” the report said, but noted that the U.S.-based ThREE Consulting has applied to the Department of Energy for funding to study the feasibility of the hydrogen-based technology.

David Hess, a former secretary of Pennsylvania’s Department of Environmental Protection, said any attempt to use hydrogen to make green steel would mean starting fresh in a state that currently has no hydrogen capacity on an industrial scale.

“We don’t have a hydrogen economy in Pennsylvania; we would have to build it from scratch,” he said. “You need the plant to make it, you need to get it where it needs to be, the people who are using it must have the technology to be able to use it. There are a lot of moving parts to even put numbers to.”

By requiring the new production of emission-free electricity, green steel could stimulate industries such as wind and solar, creating jobs in the installation and grid-maintenance industries, and reinforcing the positive economic effects for the region, the report said.

It used U.S. Steel’s Mon Valley Works—an integrated steelmaking operation with three sites in southwest Pennsylvania and one near Philadelphia—as a model for the potential adoption of green steel. The company is already planning net zero in carbon emissions by 2050.

In 2021, U.S. Steel canceled a planned $1.3 billion investment in the Mon Valley Works, and said three of the coke batteries at its Clairton plant would be permanently idled. The net-zero goal will rely on increasing its use of electric arc furnaces and the capture and sequestration of carbon, the company has said.

U.S. Steel declined to comment immediately on the Institute’s report, but noted that it has already committed, along with Shell and the Norwegian energy company Equinor, to a “collaborative clean energy hub” in the Ohio-Pennsylvania-West Virginia region. The hub would focus on decarbonization strategies including carbon capture utilization and storage (CCUS) and hydrogen production and utilization. CCUS technologies remove carbon dioxide emissions from smokestacks and then either store the gas underground in geological formations or use it to make products like concrete blocks.

All three companies aim for net-zero carbon emissions by 2050, and are seeking U.S. Department of Energy funds designated for the creation of 6-10 such hubs around the country. One of them would be the Decarbonization Network of Appalachia (DNA) hub, which has been endorsed by Pennsylvania Gov. Josh Shapiro, a Democrat.

The report did not offer estimates for the investment needed to convert the regional industry to green steel production, but quoted a 2021 estimate from the GreenSteel for Europe group that conversion of a plant to the technology to produce 1 million tons a year would cost $266 million.

In 2019, Pennsylvania’s industrial sector produced more than 86 million tons of greenhouse gases, and a third of the state’s total CO2 output. Using the green process to produce 2 million tons of steel a year would cut the state’s CO2-equivalent emissions by 4.6 percent from the 2019 level.

Reducing emissions would save the state an estimated $380 million a year in health, social and environmental costs, according to a “social cost of carbon” calculation used by the state in its 2019 Climate Action Plan. Allegheny County in southwest Pennsylvania has some of the state’s worst air quality because naturally occurring temperature inversions trap emissions from the steel industry that has been operating there for more than a century.

The biggest challenge to producing green steel is that only 3 percent of Pennsylvania’s electricity currently comes from renewable sources, the report said. It estimated that making 2 million tons a year of fossil-fuel free steel would need the state to more than double its wind and solar generation from 2022 levels.

Adoption of green steel could increase greenhouse gas emission if demand for green-steel electricity exceeds the supply from renewable sources, the report said. At that point, power would be drawn from non-renewable sources, and the extra demand from the steel industry could slow the buildout of renewable power for other users.

“The additional demand created by fossil fuel-free steel production could strain the ongoing and emerging installation of solar and wind,” the report said. “Paradoxically, fossil fuel-free steel production could potentially divert or delay grid decarbonization if not designed properly.”

Another possible obstacle to green steel would be the manufacture and transportation of hydrogen, the report said. There are concerns that it could make pipelines and their welds brittle and prone to leaks, while trucking the gas to steelmaking sites could be expensive.

But the report said significant help could come from recent federal laws— the Inflation Reduction Act, the Bipartisan Infrastructure Investment and Jobs Act, and the CHIPS and Science Act—that were designed to help curb industrial emissions while renewing national infrastructure.

As regulators, investors and the public demand more action from industry to curb emissions, the region could benefit by becoming an early adopter of green-steel manufacturing, the report said.

“As more producers face regulatory and social pressure to decarbonize their production processes and supply chains, they are likely to invest in locations that already have significant clean energy infrastructure,” the report said. “In recent case studies, firms that were first-movers in carbon neutrality enjoyed significant positive economic benefits, including increased sales, customer retention, and lower operating costs.”

The paper underlines the conclusions of another study by the Rocky Mountain Institute in 2019, which found that a low-emissions approach to manufacturing was being taken by producers of only 8 percent of the world’s steel. That study said a 100-fold “step-change” in the industry’s approach to carbon emissions is needed for it to be consistent with holding the global temperature rise to 1.5 degrees Celsius.