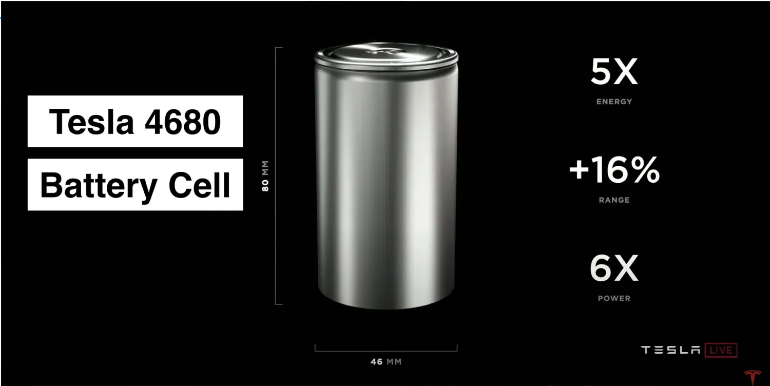

Tesla has been working on 4680 battery cells that are taller and wider than the cells many companies are using. But it’s not just the format that is different. What’s inside is what makes the difference. A traditional lithium ion battery uses a wet paste to coat the anode and the cathode. In the manufacturing process, a considerable amount of room in the factory is devoted to drying those coatings before the whole thing gets rolled up and stuffed inside the outer metal shell to become what we think of as a battery cell.

Many readers may recall that Tesla bought a company called Maxwell Technologies five years ago, primarily for its dry electrode process. Dry coating means less energy needed for drying, less floor space in the factory for the drying process, and lower production costs. It’s a win/win/win situation for a manufacturer that should lead to lower prices for consumers — if you can make the dry coating process work.

Tesla is currently manufacturing 4680 cells that use dry coated electrodes at the Gigafactory in Austin, Texas where it is building the Model Y and the Cybertruck. Reuters says it has spoken to nine people who claim to know what is going on inside the Austin Gigafactory. Those sources say Tesla has yet to crack the dry coating process at the scale needed to make 4680 batteries fast enough to hit its production targets.

Tesla says it expects to produce 250,000 of those vehicles by 2025 but the current run rate is only enough to power 24,000 Cybertrucks a year — one tenth of the goal. Those sources said dry coating the anode in the 4680 cells was not problematic but Tesla was struggling with the perfecting the same technique for the cathode, which is the most expensive component in a battery.

Dry Coating 4680 Cells Is Hard To Do

Dry coating anodes and cathodes is proven in the laboratory, as well as for smaller energy storage devices such as super capacitors, according to Yuan Gao, a battery technology consultant. “But no one has done it so far for large EV batteries at a mass scale and at a high enough speed. Tesla is the first one to try to commercialize this,” said Gao, who has worked in the industry for three decades. “The challenge is that not only does Tesla have to scale it up and speed up the process, it also must develop its own equipment and tools. It’s daunting to say the least,” he said.

According to three of the sources, the 4680 battery packs in Cybertrucks have an estimated 1,360 individual cells. That means Tesla would need to make 340 million cells a year — or almost a million a day — to supply 250,000 of the electric pickups. At the moment, the Gigafactory in Austin needs about 16 weeks to make 10 million 4680 cells, according to calculations made by Reuters based on information provided by those sources.

Tesla has indicated it wants to use the 4680 battery cells not only for the Cybertruck but also for the long rumored Model 2 (It may be called something else when it goes into production in a couple or years). At the present time, the company is not making nearly enough dry coated 4680 battery cells for both vehicles.

Tesla has some limited production capacity for 4680 cells in Fremont, California but its plant there is mainly for pilot production. Panasonic, one of Tesla’s primary battery suppliers, is planning to build at least two plants in the United States but has only just broken ground on the first.

Some of the sources who spoke with Reuters believe Tesla’s progress with scaling up 4680 production will likely gain momentum once it achieves stability with the production on one production line. They said Tesla had been focusing on establishing robust know-how to produce batteries without flaws first time round. It’s a time-consuming process but, “once you crack the code and establish stability, it is like exponential. Speed would pick up. There is already a lot of traction in dry coating,” one source said.

Drew Baglino, the head of Tesla’s battery operations, said in October the company was now producing 4680 cells on two production lines in Austin and plans to install a total of eight lines there in two phases, with the last four due to be running in late 2024.

Replicating established know-how from one production line to the next is difficult, with one source saying only about 5 percent of cells made on profitable production lines are discarded but scrappage rates could increase to between 30 percent and 50 percent and hover there for several months as each new line gets going.

4680 Struggles Continue

Another source said Tesla’s dry coating method for cathodes was not proving to be any faster than the old wet process, though scrap rates had dropped to as low as 10% to 20%. The sources said Tesla was struggling to mix the cathode materials — which include lithium, manganese, and nickel — with a binder and stick them to a metallic foil to produce a cathode without using moisture.

Two of the people said the process worked for small amounts but when Tesla tried to scale it up, a lot of heat was generated and this melted the binder, which one of the sources believed was polytetrafluoroethylene, more commonly known as Teflon. “If you melt the glue, pretty soon everything will become one big chunk of gooey mess,” a source said.

Equally problematic for Tesla are the machines used to coat the metallic foil to produce battery electrodes — equipment which is akin to huge magazine and newspaper printing machines with large rollers. To accelerate cell production, Tesla is trying to coat multiple strips of magnetic foil with active battery materials at the same time, and at high speeds.

That calls for large, wide rollers, as well as applying tremendous force to press the materials onto the foil. But because the rollers are large and wide, applying pressure evenly is proving to be a challenge. When pressure is not applied evenly, Tesla gets electrodes with uneven surfaces and thickness, which are of no use for its battery cells and need to be scrapped.

One of the sources with knowledge of the matter said specifically it was about building data infrastructure around Tesla’s battery development, manufacturing and in-field use because in some cases the flaws were hidden in the coating and did not show up until a few months later. In other words, Tesla does not yet know yet which dry cells are good and which ones need to be junked, the source said. Baglino told a fireside chat at a battery conference in March that Tesla was still building a completely new quality verification system so they could weed out cells with flaws in coating.

The point on the Reuters reporting is not to say that Tesla will never make dry coated 4680 battery cells but that the process is taking some time to perfect. The spirit of Tesla is reminiscent of the US military during the Second World War, when a popular expression was, “The difficult we do right away. The impossible takes a little longer.” Seems like the perfect motto for Elon and his Musketeers.