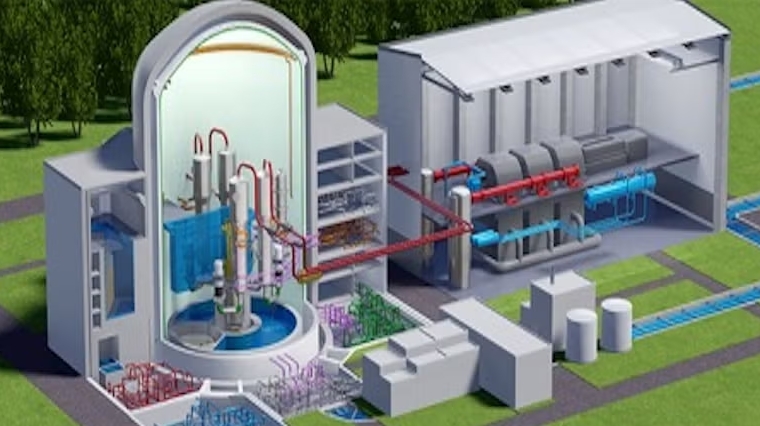

The DPSC module features reinforced concrete encased between two continuous steel plates, offering enhanced durability and flexibility. These modules can be prefabricated off-site, transported, and assembled rapidly, reducing labor costs and construction timelines. The design allows modules to be joined to form structural walls, floors, or foundation sections for reactor buildings.

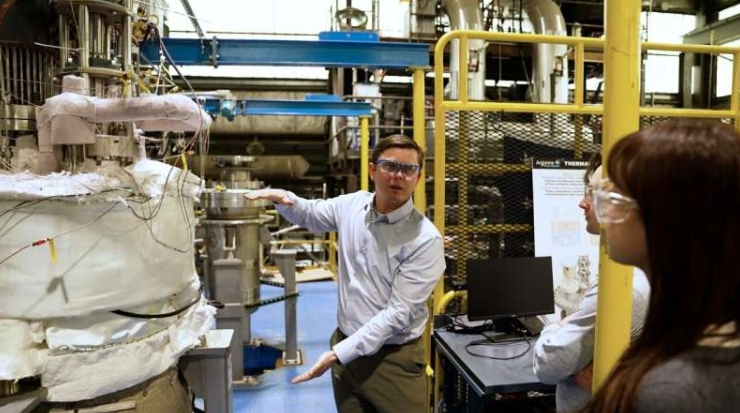

Testing of the DPSC modules took place at Purdue University’s Bowen Laboratory in Lafayette, Indiana. Researchers filled the modules with concrete to replicate a reactor containment wall and subjected them to various stress tests, including conditions simulating an earthquake, to evaluate performance under real-world scenarios.

Luke Voss, programme manager at Idaho National Laboratory, stated: “The DPSC system tests at Purdue exceeded our expectations. We are very excited and enthusiastic about the use of this construction technology to help save time and money in the deployment of new nuclear reactors.”

Sean Sexstone, Executive Vice President, Advanced Nuclear, GE Hitachi, stated: “The successful design, fabrication and testing of DPSC modules demonstrates the potential of this advanced fabrication and construction technology to lead to cost savings and improved project schedules in the deployment of small modular reactors.”

Data from the small-scale tests will support efforts to license the DPSC modules for future reactor containment construction. The NRIC is reviewing a GEH proposal to construct a portion of a reactor containment building using the DPSC design, incorporating digital twin technologies and non-destructive evaluation techniques developed in the project’s initial phase.

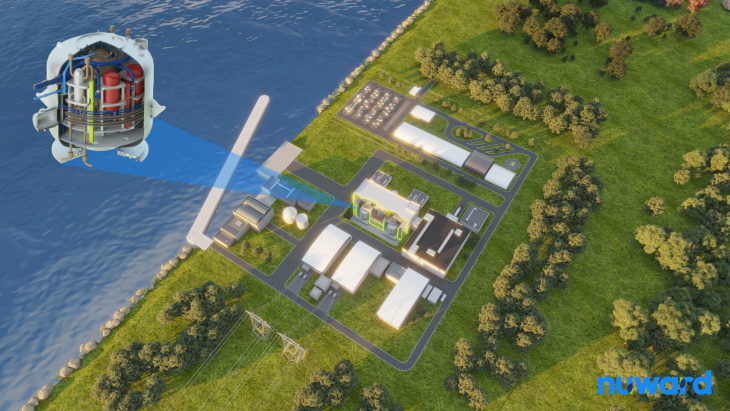

GEH plans to implement the DPSC technology in its first four BWRX-300 small modular reactors in Darlington, Ontario, Canada. Ontario Power Generation received a construction license for these reactors earlier this month, marking a significant step toward deploying the technology in operational nuclear facilities.

This advancement highlights Mercedes-Benz is introducing its new EQE electric SUV in Australia with deliveries set to begin from the end of April. The EQE is available in two variants – the EQE 350 and EQE 53 AMG, with prices starting from $134,900 and $199,900 respectively.

The EQE 350 has a 90kWh battery pack, a 215kW/565Nm single motor driving the rear wheels, and a claimed range of 552km. The high-performance EQE 53 AMG variant has a 100kWh battery, 484kW/950Nm from dual motors, and a range of 470km. The EQE 53 also gets adaptive air suspension, rear-wheel steering, and AMG-specific styling.

“With its sleek design, cutting-edge technology, and impressive electric range, the EQE sets a new benchmark for luxury electric SUVs in Australia,” said Michael Trilse, product manager, Mercedes-Benz Australia.

Both variants come with a five-year/unlimited-kilometre warranty and an eight-year/160,000km battery warranty. Deliveries for the EQE will commence in Australia from late April 2025, with orders now open.

The EQE is built on Mercedes-Benz’s EVA2 platform and features a 12.8-inch central touchscreen, a 12.3-inch driver display, and a head-up display. Standard features include a panoramic sunroof, heated and ventilated front seats, a Burmester sound system, and advanced driver assistance systems.

“The EQE offers Australian customers a compelling blend of luxury, performance, and sustainability, making it an ideal choice for those transitioning to electric mobility,” Trilse added.

The EQE 350 has a single motor producing 215kW/565Nm, while the EQE 53 AMG’s dual motors deliver 484kW/950Nm, enabling a 0-100km/h sprint in just