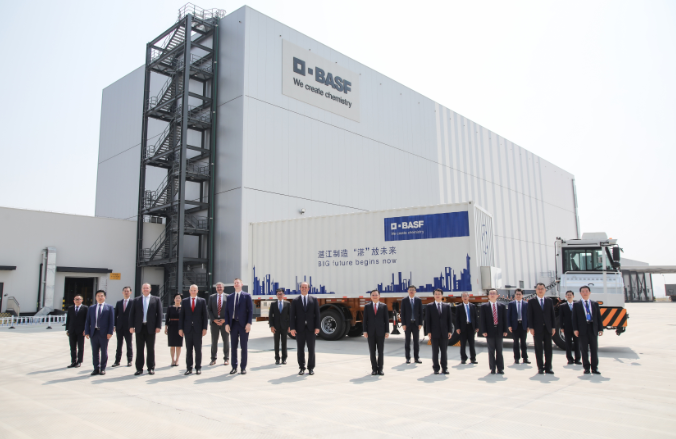

The collaboration aims to leverage China’s position as a leading hub for textile supply chains and innovation. The facility will prioritize developing high-quality, sustainable yarn products to serve the growing market for eco-friendly textiles. By establishing local production, Eastman seeks to improve supply chain efficiency and responsiveness to customer needs in the region.

Ruth Farrell, general manager of Eastman’s textiles business, stated: “China is the world’s largest textile supply chain hub and a frontier for product and technology innovation. This strategic partnership will provide us with greater capacity and further enhance the innovation and product development capabilities of Naia cellulose-acetate yarn while enabling Eastman to fulfill its brand promise of making sustainable textiles accessible to all.”

The partnership strengthens Eastman’s presence in China, reflecting its commitment to delivering innovative and sustainable textile solutions. The joint facility will integrate advanced technology and local expertise to produce yarns that meet global quality standards while supporting environmentally conscious practices in the textile industry.

Congdeng Yang, director of the Huafon-Eastman collaboration program, commented: “Through cooperation with Eastman, we look forward to combining local advantages with international resources to achieve a fully localized chain — from technological innovation, product development and production to service — and jointly promoting the sustainable development of the textiles industry.”

In addition to the new facility in China, Eastman continues to produce Naia cellulose-acetate yarn at its manufacturing site in Barcelona, Spain. This dual production strategy enhances the company’s global capacity to supply sustainable textile materials, catering to diverse markets while maintaining a focus on quality and innovation.

The Eastman-Huafon partnership aligns with the increasing demand for sustainable textiles worldwide. By combining Huafon’s local expertise with Eastman’s advanced technology, the joint facility is poised to deliver innovative, high-quality yarn products, contributing to the sustainable growth of the textile industry in China and beyond.