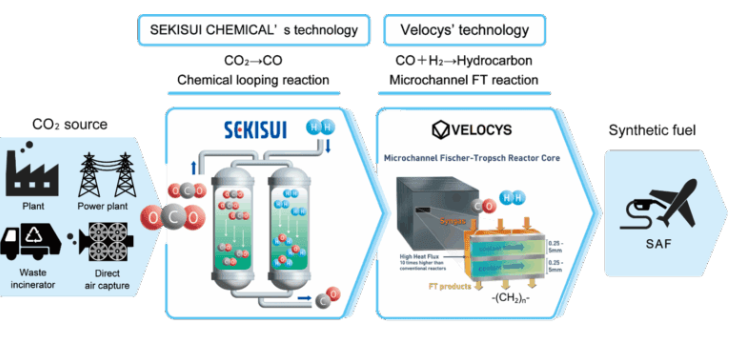

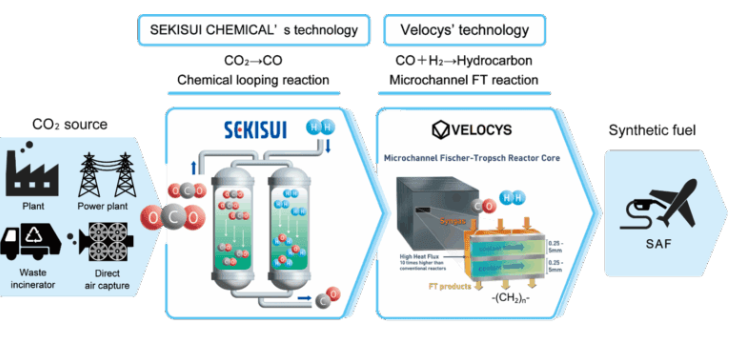

Sekisui Chemical Co. Ltd., based in Osaka City, Japan, and Velocys Inc., headquartered in Houston, Texas, have signed a memorandum of understanding to collaborate on advancing production technology for electro-Sustainable Aviation Fuel (e-SAF). This partnership integrates Sekisui’s CO2-to-CO chemical looping technology with Velocys’ Fischer-Tropsch microchannel reactor technology to produce synthetic fuel from CO2, contributing to global efforts to reduce carbon emissions in the aviation sector.

The aviation industry accounts for approximately 2.6% of global CO2 emissions. Sustainable Aviation Fuel (SAF) is a critical solution, with estimates suggesting it could meet 65% of the sector’s CO2 reduction targets. While conventional SAF relies on waste oil and biomass, the growing demand for fuel necessitates e-SAF, produced from CO2 and hydrogen derived from renewable energy. This approach supports scalable, sustainable fuel production to meet future needs.

Sekisui Chemical’s chemical looping technology converts CO2 into carbon monoxide with over 90% efficiency, enabling the reuse of CO2 as a valuable resource while reducing reliance on fossil fuels. Velocys, with over 20 years of expertise, specializes in Fischer-Tropsch technology to transform synthetic gas—sourced from municipal waste, industrial waste, biomass, and CO2—into synthetic fuels. Its proprietary catalyst and microchannel reactor design achieve productivity six to ten times higher than conventional methods.

Tetsuo Nakanishi, Senior Managing Executive Officer at Sekisui Chemical, stated: “This partnership with Velocys leverages our CO2-to-CO technology to advance e-SAF production, contributing significantly to the aviation industry’s decarbonization goals.”

Henrik Wareborn, CEO of Velocys, stated: “By combining Sekisui’s high-yield CO2 conversion with our advanced Fischer-Tropsch technology, we aim to create a highly efficient e-SAF production process that supports a sustainable future.”

The collaboration focuses on merging Sekisui’s technology, which achieves over 90% reaction yield, with Velocys’ Fischer-Tropsch process, offering 90–95% CO conversion rates. This integration aims to develop an efficient e-SAF manufacturing system using CO2 as a primary feedstock, supporting the aviation industry’s sustainability objectives. The partnership seeks to enhance the scalability and adoption of e-SAF, aligning with global efforts to reduce carbon emissions.

By combining their expertise, Sekisui Chemical and Velocys are advancing innovative solutions for cleaner aviation fuels. This initiative supports the broader goal of decarbonizing the aviation sector, fostering sustainable energy practices, and contributing to a more environmentally responsible global energy landscape.