Battery power has never been in greater demand, and a wide range of new applications that require such power are emerging daily. That increased demand is accompanied by the need for more production, which in turn requires the highest degrees of contemporary quality control.

Accurate measurement is the key to enabling these new production facilities to meet that demand while ensuring the levels of consistent quality.

“Net zero” is on everyone’s lips. The pervasive use of fossil fuels is becoming unsustainable if we are to arrest the climate change that has become all too obvious, even to the casual observer.

One of the primary alternatives that has rapidly gained traction is the adoption of ever-improving portable electric energy sources. Battery power is at last capturing the imagination in both industrial and consumer markets, and a large part of that acceptance is due to battery technologies being proven as reliable, efficient, and long-lasting forms of power. However, to maintain and even accelerate that confidence, battery power storage and discharge capabilities need to be reliably and accurately measured. “Range anxiety” is not a selling point for electric vehicles (EVs), but hard evidence is now available that can alleviate such concerns, and that evidence is gained highly accurate measurement devices.

Many are already familiar with lithium-ion (li-ion) batteries, which continue to lead the way in EV applications, predominantly for transport and automatic uses due to their long life and dependability.

The evidence for their popularity lies in the fact that demand for such batteries continues to rise exponentially around the world, and manufacturing (Figure 1) must keep pace. However, to do that—and maintain a reputation for quality goods—manufacturers must adopt even more rigorous test, analysis and verification procedures.

A Battery of Parts Becomes a Whole Lot More

A modern battery is much more than a collection of electrochemical cells. Although it’s true that the basic composition of li-ion battery cells remains relatively simple, i.e., a copper anode, an aluminum cathode, a separator, and a liquid electrolyte, manufacturing them is an altogether more involved and complex process as they proceed through a drying process to evaporate the solvent.

1. Production of lithium-ion batteries at a battery factory. Courtesy: ABB

Physical properties can be adjusted by compressing the electrodes in a smoothing “calendaring” process to provide a smooth, glossy finish. They then progress to a slitting and stamping stage. Any remaining moisture is removed under vacuum pressure before the assembled electrodes are fully dried prior to the electrodes and separators being layered to form a cell.

Finally, the electrodes and separators are sealed and filled with electrolyte, and there you have your portable power source.

Measuring Quality Through Quality Measurement

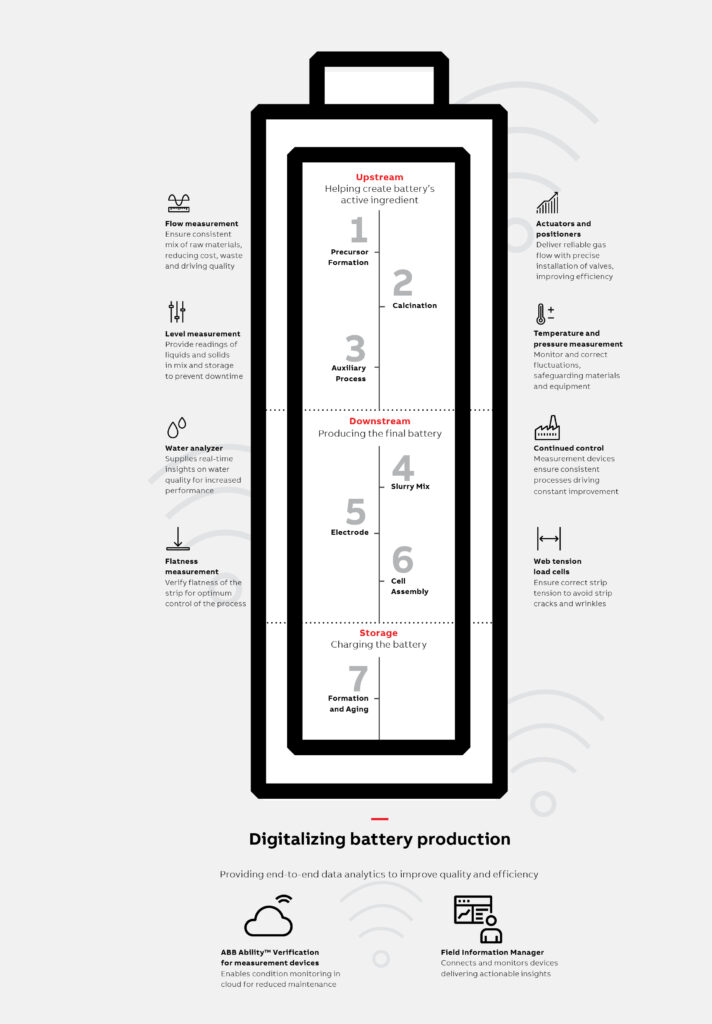

As batteries (Figure 2) move through the manufacturing process, a wide range of parameters must be measured, tested and analyzed. Items like pressure, temperature and flow measurement, water quality and gas analysis, coupled with level and force measurement, must all be precisely calculated at various stages of the production cycle to ensure consistency and quality throughout.

2. Battery cells on a production line. Courtesy: ABB

And the recipe for those measurements is precise. For example, slurry must be mixed at 20C to 40C to ensure consistency of particle size, purity and viscosity, all of which have a direct impact on quality. To ensure a dry film thickness coating of +/- 2 g/m2, the coating’s application must be accurately measured while it is taking place to ensure that surface quality and adhesion between the substrate and the coating are maintained.

The battery drying process is also crucial. Temperature must be strictly controlled as well as other critical parameters such as residual humidity.

A calendaring roller speed of 60 to 100 m/min must be maintained at temperatures between 50C and 250C. And because burr waste can sometimes be introduced as a result of the slitting process, the degree of particle contamination during the cutting process must also be closely monitored and measured.

The vacuum drying stage also demands high accuracy measurement to maintain a working pressure of between 0.07 and 1000 mbar and a temperature of 60C to 150C.

Electrolyte filling brings the process near to completion, and again requires the accurate measurement of pressure to approximately 0.01 mbar to ensure the delivery of a precise quantity of electrolyte. Finally, cell aging involves measuring temperatures of up to 50C over extended periods.

It’s easy to see that with so many moving parts requiring such high precision to ensure quality and avoid wasting valuable raw materials, accurate testing, measurement, and analysis are crucial components at every stage. Preventing wastage to ensure delivery to global supply chains is more important than ever as the demand for battery-driven power races forward, and the desire to reduce dependence on fossil fuel-originated power grows stronger.

Making the Transition From Legacy Analog

It’s true that not everyone has made a full transition to digital technology. Despite the multiple advantages of digital accuracy, numerous industries still employ legacy analog instruments. However, that is less than optimal for contemporary production requirements, not least for the precision measurements required for the lengthy and complex li-ion battery production process.

For example, traditional analog meters typically have a known flaw in which the transmitting range of an instrument and the input range of the receiving instrument use a varying electrical signal—for example 0 – 500 ml/s in a flow metering application—which can cause operators to waste time and money trying to locate ‘lost’ measurements due to those variances.

Analog devices served their purpose but have had their day. Digital instruments (Figure 3) now provide far greater levels of accuracy that are essential for ensuring that each battery produced meets expected standards, which not only reduces raw material waste but improves safety, and ultimately profitability due to the consistent delivery of top-quality goods.

3. This graphic illustrates the digitization of battery production. Source: ABB

This is because digital instrumentation enables multiple values such as density, temperature, or pressure to be combined in a single, often bi-directional transmission. In other words, digital can do many things at once. Analog cannot. Time is still money, so the ability to accurately obtain multiple measurements in a single transaction is a significant cost-saver.

Digital instruments are also much easier to use and much faster to deploy. Modern digital device user interfaces, or UIs, are highly sophisticated in their ability to quickly and accurately display information. Configuration options are also much more flexible, and intuitive, which not only saves time in training and on-site usage but enables far more to be achieved in a shorter amount of time. It also substantially reduces errors because, in most cases, digital measurement devices have in-built intelligence to ensure they make themselves clearly understood to the user or, if necessary, self-correct to ensure that the margin for human error is next to nil.

4. ABB’s next generation range of sensors bring together more than 70 years of pioneering pH sensor development and application expertise with the latest advanced digital technology and sensor diagnostics. Courtesy: ABB

Another substantial differentiator of digital instruments (Figure 4) is that they are also excellent fault finders. Analog devices often leave the user guessing as to where a fault may lie, again requiring extensive fault-finding missions throughout a production chain. Digital instruments, on the other hand, can check the validity of their data in real time and rapidly pinpoint the location of any fault. That ability enables operators to rapidly respond, often from anywhere in the world, to resolve any malfunction or out-of-spec performance anomaly.

Put to the Test for Success

One major li-ion battery manufacturer in Sweden recently partnered with ABB to fast-track the construction and delivery of a large gigafactory plant design that would fully optimize its battery production capabilities after start-up. The plant uses a range of ABB power management system instrumentation (Figure 5), transformers, and switchgear while simultaneously minimizing risk and costs. The result is that the factory is now Europe’s largest battery manufacturer and one of the most-efficient and productive of its kind in the world.

5. ABB’s CoriolisMaster series is among the tools offering a wide range of meter sizes that provide precise measurement of mass flow, volume flow, density, temperature and concentration. Courtesy: ABB

A Powerful Transformation

The ability to use digital instruments to generate and access highly accurate data, and almost instantly make intelligent operational decisions based on that verified data, gives the operator far more confidence and control. In the case of li-ion battery manufacturers in particular, digital advances enable them to better meet demand while reducing costs and wastage, the benefits of which all accrue to not only profitability, but a sustainable energy future that can be increasingly battery-powered and that much closer to a “net zero” future.